This is the first in a series of articles about battery power and its adjacent industries and processes. Check out our other post, "Application Spotlight: Solvent Recovery and Battery Liners."

Today, energy comes from a wide range of sources. The share of that collective power that comes from renewable energy sources continues to grow. In fact, in 2019, it was estimated that just under 20% of electricity generated at utility-scale electricity generation facilities in the United States was from renewable energy sources.[1]

Read More

Topics:

Computer & Electronics Cooling,

HVAC,

Coils,

Engineering

In industries like commercial and industrial HVAC, there’s an understandably massive focus on innovations aimed at improving efficiency. Billions of dollars are spent every year on research and development to drive down operating costs without compromising on performance. Doing more with less is the name of the game, and included among the measures intended to do so is the economizer.

Read More

Topics:

Power Generation,

HVAC,

Heat Exchangers,

Efficiency,

Engineering

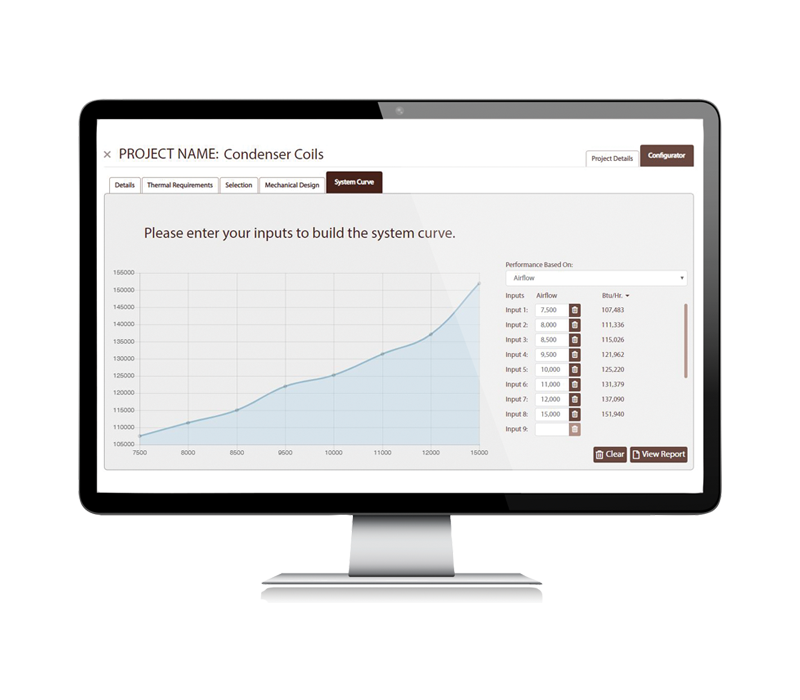

We’re super excited to announce that we’ve validated the performance ratings for R-449A and R-448A condensers in Enterprise, our coil selection software. We believe the condenser coil performance model we’ve developed is the most comprehensive and accurate of its kinds in the industry.

We wanted to use this post to briefly explain our testing methodology to our users. We’ll also touch on why performance modeling for these refrigerants has been challenging in the past, and how we plan to improve our model over time.

Read More

Topics:

Heat Exchangers,

Efficiency,

Expertise,

Reliability,

Engineering,

Refrigerants

Hydronics systems? Football? While you may not hear those terms in the same breath every day, there’s actually a mind-blowing amount of design and engineering that help keep football field surfaces playable through the cold winter months.

First, some context

With this year’s big game being played in Tampa Bay, frozen ground won’t play a factor, but January's NFC championship game took place at the site of probably the most famous instance of frozen turf in history - historic Lambeau Field.

Read More

Topics:

Food Storage & Processing,

HVAC,

Expertise,

Reliability,

Engineering

There are a number of industrial processes that require extremely cold temperatures – sometimes as cold as -150°F. For the equipment used in such applications, those low temperatures pose some unique challenges. In this post, we’ll detail some of the temperatures involved and outline some things to consider with regard to heat exchanger design and materials for low-temp applications.

Read More

Topics:

Food Storage & Processing,

Coils,

Heat Exchangers,

Expertise,

Reliability,

Engineering

Cooling data center IT equipment using air has been the industry standard for as long as there's been a data center industry. However, advances in computing technology have pushed the limits of what air-cooled systems are able to efficiently keep cool, as the amount of power needed to operate those systems increases.

Read More

Topics:

Computer & Electronics Cooling,

HVAC,

Coils,

Expertise,

Engineering

Our refrigerant focus series consists of deep dives into the history, properties, suitable applications and pros and cons of some of today’s common refrigerants. This installment will focus on R-410A.

Read More

Topics:

Refrigerated Display Case,

Heat Exchangers,

Efficiency,

Reliability,

Engineering

When designing a heat exchanger, an engineer should not only consider thermal performance, but also external influences that can negatively impact thermal performance, such as fouling.

Read More

Topics:

Power Generation,

HVAC,

Coils,

Nuclear Products,

Efficiency,

Expertise,

Reliability,

Engineering

Gas-tungsten arc welding (GTAW), or more commonly, Tungsten Inert Gas welding (TIG), is a method of arc welding named for the non-consumable tungsten electrode used during the process. TIG welding isn’t the best option in some industries, but as coil manufacturers, it makes sense for us.

Read More

Topics:

Gas Compression,

Military,

Food Storage & Processing,

Power Generation,

Heat Exchangers,

Nuclear Products,

Expertise,

Quality,

Reliability,

Engineering

This article has been updated. It is accurate as of Feb. 8, 2022

For low-temperature hydronic systems, systems in which chillers and AHUs are located outdoors, or other equipment used in low-temperature processes, some form of glycol is a critical ingredient. It works to lower the fluid’s freezing temperature, enabling lower-temperature operation and preventing freezing.

Read More

Topics:

Food Storage & Processing,

Ground Support,

Coils,

Heat Exchangers,

Efficiency,

Expertise,

Reliability,

Engineering