2024 Year in Review for HVAC and Manufacturing Sectors

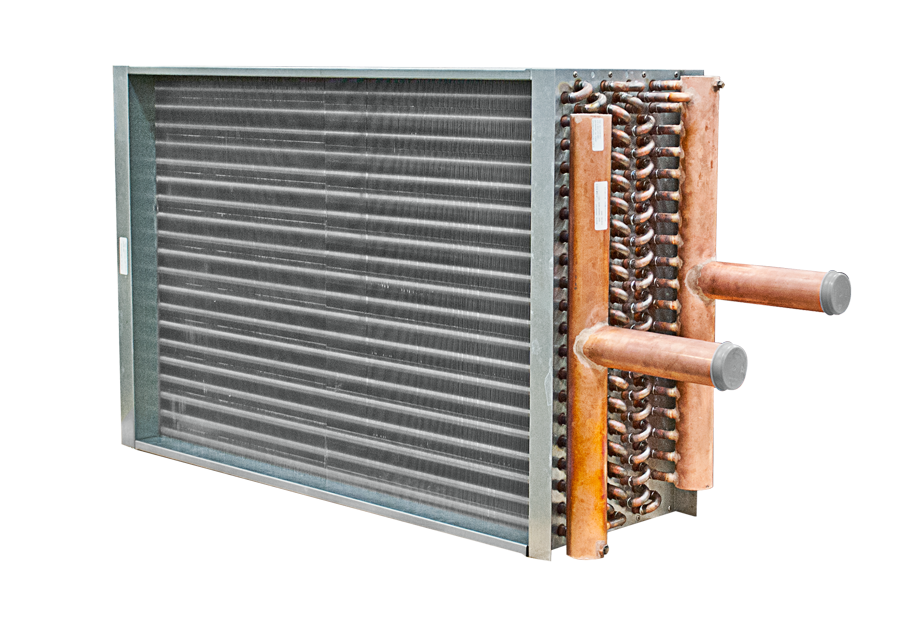

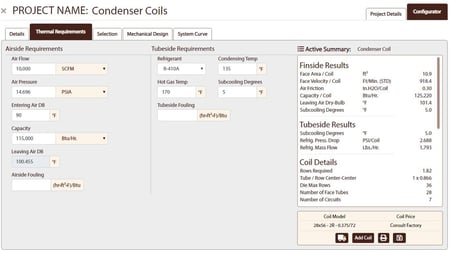

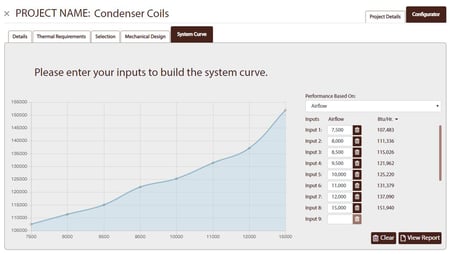

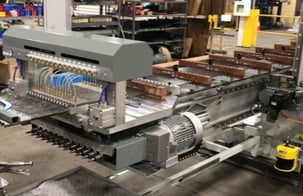

Well, believe it or not, 2024 is just about over. It’s been quite a busy year in the world of HVAC, manufacturing, and heat transfer, and we thought we’d run through a brief recap of some of this year’s biggest headlines before we officially turn the calendar to 2025. Learn More