3 Advantages of TIG Welding in Manufacturing

Gas-tungsten arc welding (GTAW), or more commonly, Tungsten Inert Gas welding (TIG), is a method of arc welding named for the non-consumable tungsten electrode used during the process. TIG welding isn’t the best option in some industries, but as coil manufacturers, it makes sense for us. Learn More

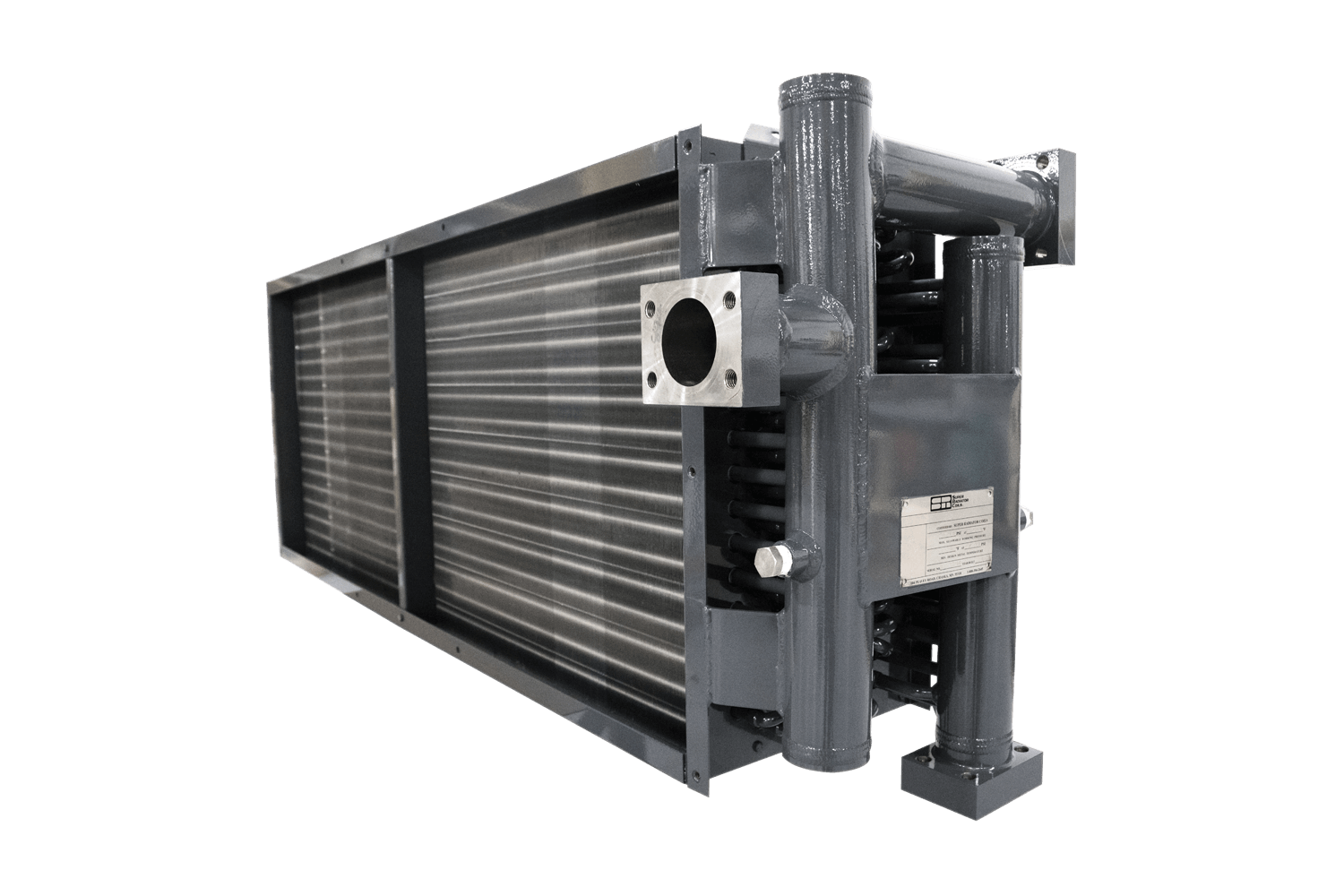

.png?width=1308&height=1184&name=Compressed-Gas-Cooler_1-flip-min%20(1).png)