As a custom coil manufacturer, we often speak with facilities managers and maintenance professionals about coil replacements, upgrades, and retrofits. These jobs often require us to design a coil for an existing space, which can be tricky if you're not sure what to look for. For this post we’ll explain that process, including:

- Common size-in-place scenarios for commercial HVAC coils

- Some best practices when replacing a coil

- Other important coil replacement considerations

Read More

Topics:

HVAC,

Coils

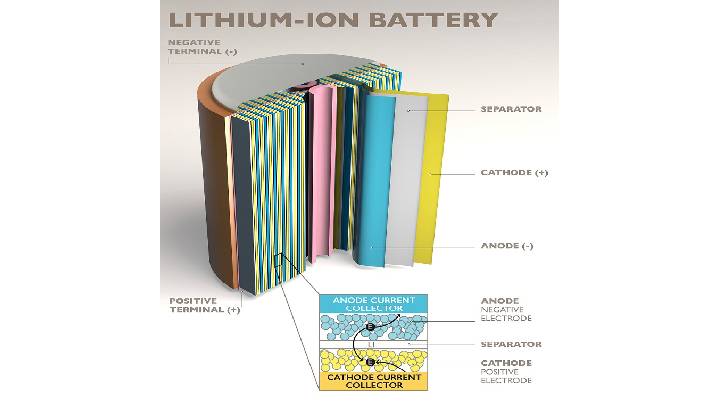

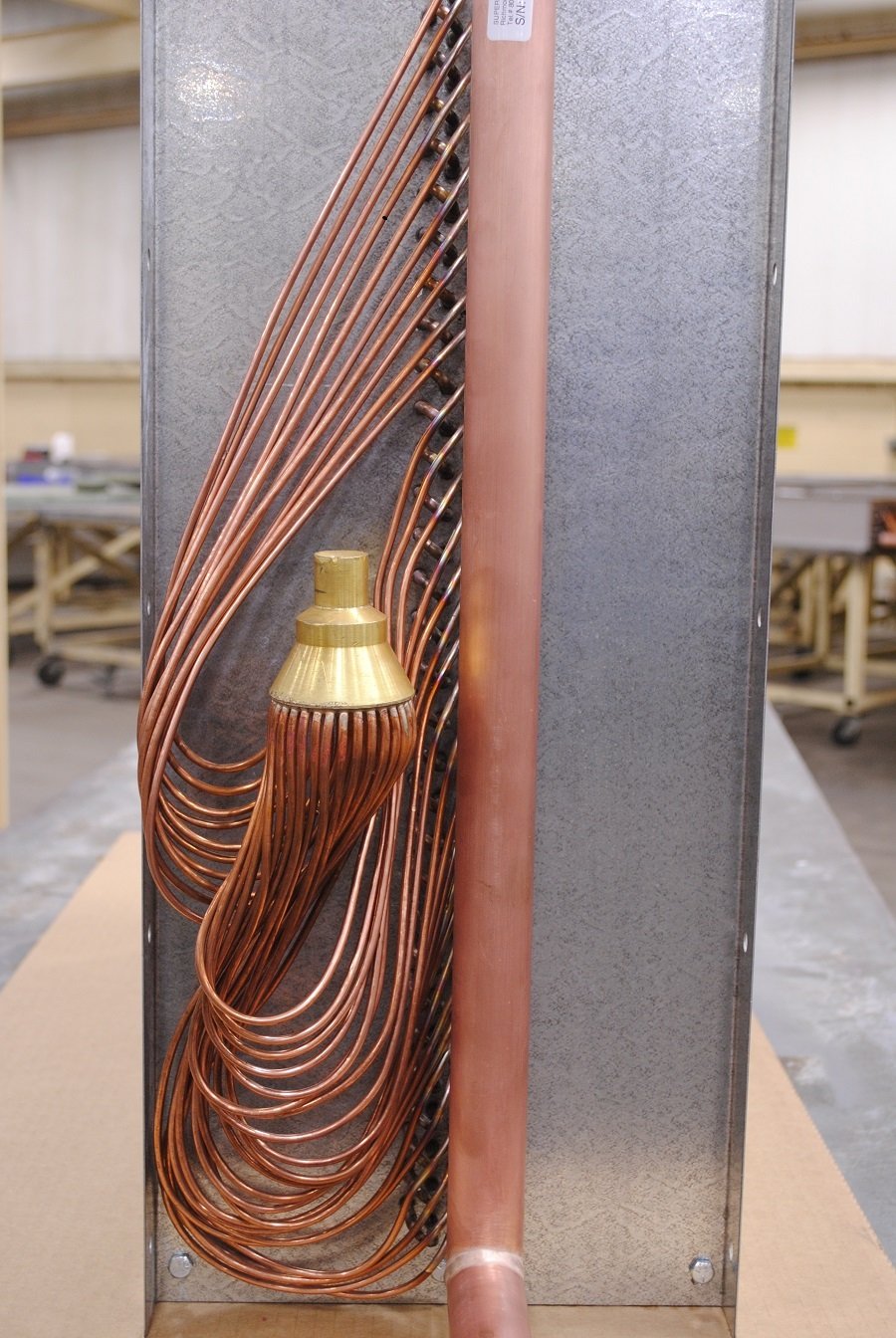

Every so often, we like to take a detailed look at the applications for which our products are used. This installment will focus on solvent recovery applications during the production of battery products. In this post we’ll answer the questions:

- What is solvent recovery?

- How is solvent recovery used in battery liner production?

- What role does heat transfer play in the process?

This is the second of a series of articles about battery power and its adjacent industries and processes. Check out the first post in the series - “Battery Storage Facility Cooling System Design.”

Read More

Topics:

Coils,

Efficiency,

Expertise

This is the first in a series of articles about battery power and its adjacent industries and processes. Check out our other post, "Application Spotlight: Solvent Recovery and Battery Liners."

Today, energy comes from a wide range of sources. The share of that collective power that comes from renewable energy sources continues to grow. In fact, in 2019, it was estimated that just under 20% of electricity generated at utility-scale electricity generation facilities in the United States was from renewable energy sources.[1]

Read More

Topics:

Computer & Electronics Cooling,

HVAC,

Coils,

Engineering

Early 2021's deadly cold spell in Texas in and other areas of the South led to loss of power, water quality concerns for millions, and tragically, loss of life. Abnormal temperatures pushed all manner of equipment past its breaking point, and HVAC systems were hit hard.

Read More

Topics:

HVAC,

Coils,

Quality

As far as stages go, professional football's championship game is one of the biggest out there, and there’s a small army responsible for making sure everything goes off without a hitch. Behind that army of personnel is an even larger assemblage of vehicles, equipment, and other technology that help along the way – one of which is the heat exchanger.

Heat exchangers of all shapes, sizes, and functions play a part in the Great American Game – from down on the field to very high above it. So, we thought it’d be fun to list some that help to make the big game everything we know and love.

Read More

Topics:

Refrigerated Display Case,

Food Storage & Processing,

Ground Support,

Computer & Electronics Cooling,

HVAC,

Coils,

Efficiency,

Reliability

There are a number of industrial processes that require extremely cold temperatures – sometimes as cold as -150°F. For the equipment used in such applications, those low temperatures pose some unique challenges. In this post, we’ll detail some of the temperatures involved and outline some things to consider with regard to heat exchanger design and materials for low-temp applications.

Read More

Topics:

Food Storage & Processing,

Coils,

Heat Exchangers,

Expertise,

Reliability,

Engineering

Cooling data center IT equipment using air has been the industry standard for as long as there's been a data center industry. However, advances in computing technology have pushed the limits of what air-cooled systems are able to efficiently keep cool, as the amount of power needed to operate those systems increases.

Read More

Topics:

Computer & Electronics Cooling,

HVAC,

Coils,

Expertise,

Engineering

When designing a heat exchanger, an engineer should not only consider thermal performance, but also external influences that can negatively impact thermal performance, such as fouling.

Read More

Topics:

Power Generation,

HVAC,

Coils,

Nuclear Products,

Efficiency,

Expertise,

Reliability,

Engineering

In a refrigeration circuit, the evaporator coil plays a critical role. Part of its responsibility is creating the controlled pressure drop necessary for the refrigerant to change phase, the bulk of which occurs via the system’s metering device, such as a thermostatic expansion valve (TXV).

Read More

Topics:

Refrigerated Display Case,

Computer & Electronics Cooling,

HVAC,

Coils,

Efficiency,

Expertise,

Refrigerants

This article has been updated. It is accurate as of Feb. 8, 2022

For low-temperature hydronic systems, systems in which chillers and AHUs are located outdoors, or other equipment used in low-temperature processes, some form of glycol is a critical ingredient. It works to lower the fluid’s freezing temperature, enabling lower-temperature operation and preventing freezing.

Read More

Topics:

Food Storage & Processing,

Ground Support,

Coils,

Heat Exchangers,

Efficiency,

Expertise,

Reliability,

Engineering