Causes & Solutions to Airside Coil Fouling

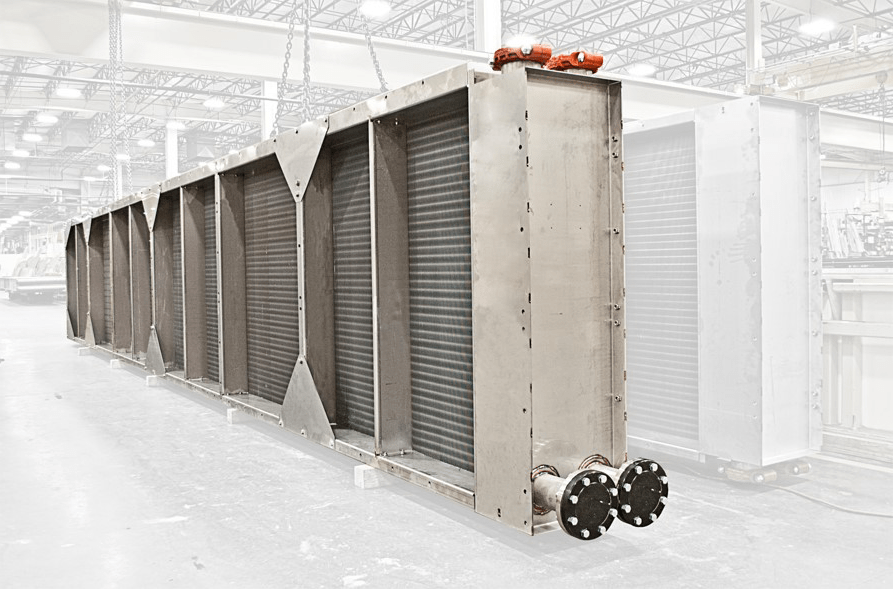

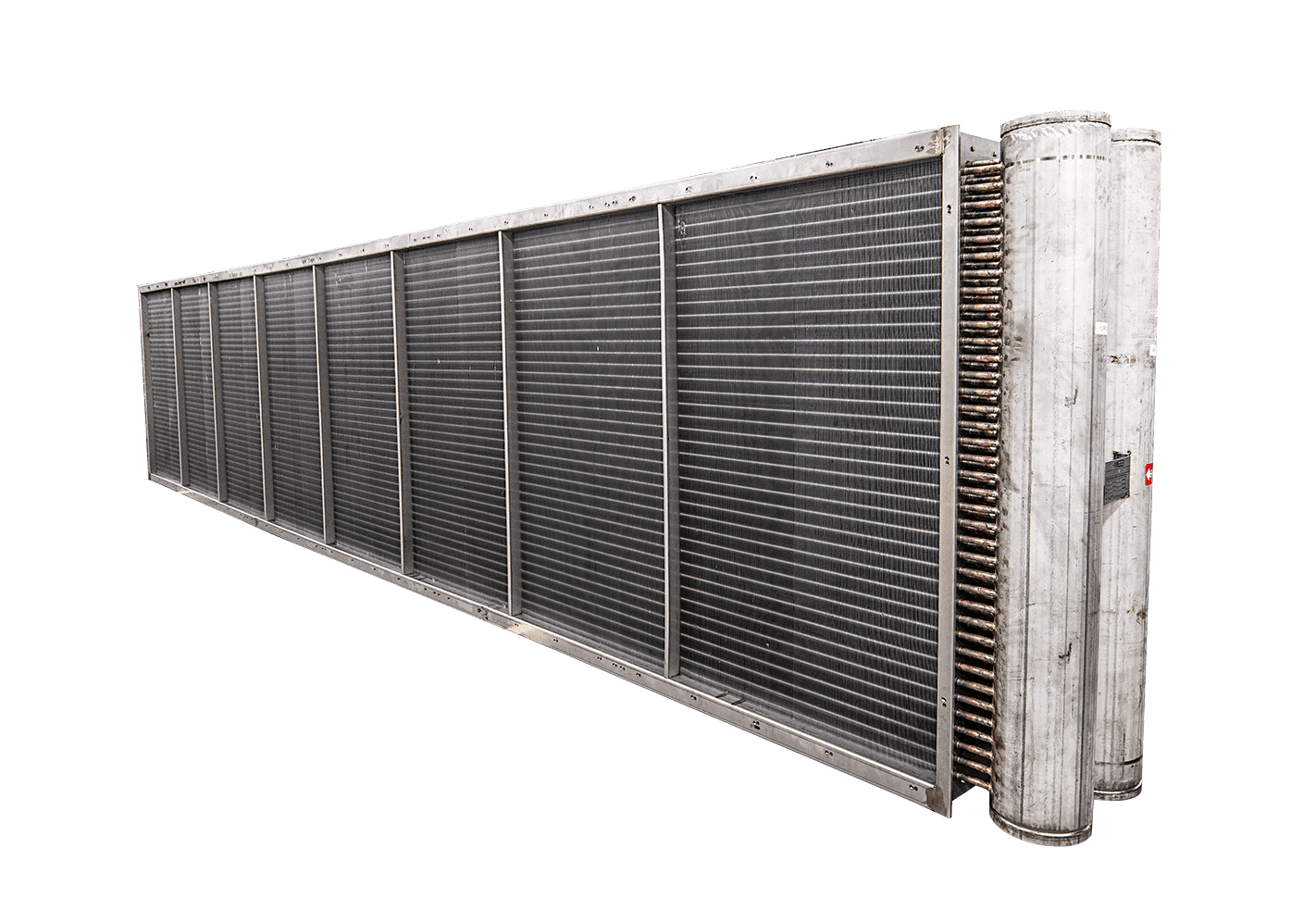

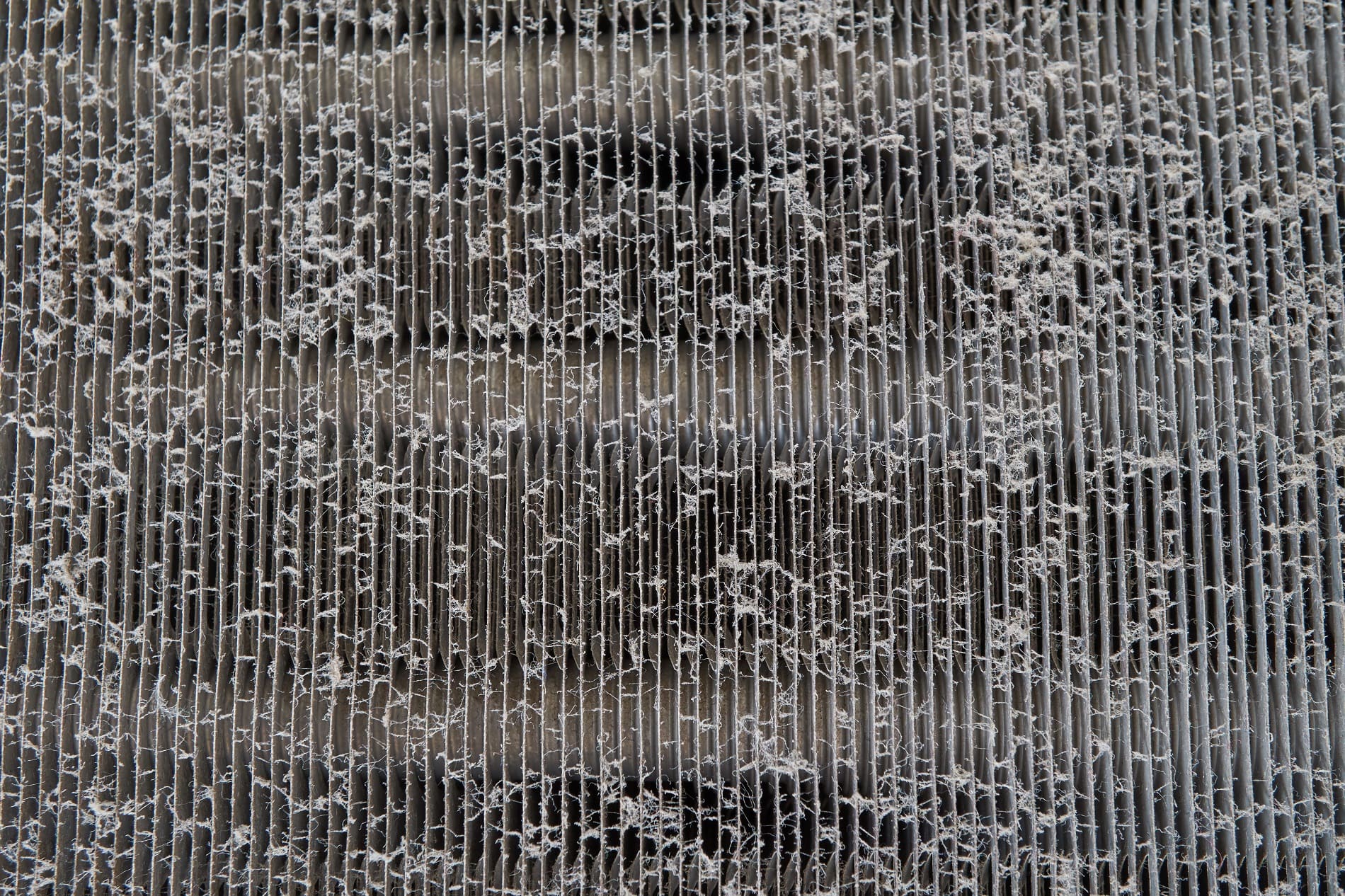

Fin tube heat exchangers are subject to fouling, which takes place as long as there is an airflow or waterflow in the unit. Defined as thermal resistance due to the accumulation of contaminants on heat transfer surfaces, fouling negatively affects heat exchanger efficiency, longevity, and increases... Learn More

.jpg?width=382&height=214&name=Turbine%20Inlet%20Heating(frost).jpg)