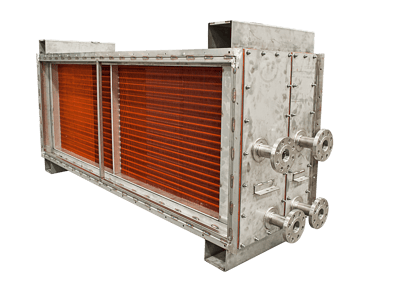

These coils dehumidify and heat outside air, condense and recover solvent vapors, and supply direct product heating for fluidized bed dryers and coolers.

Integrated heat exchangers come in direct contact with the product and add additional heat without increasing air mass flow. For some products, integrated, in-bed heat exchangers allow for more even drying and a smaller overall dryer size. These coils are typically made using a bare tube construction.

With an open system, coils preheat outdoor air, which is then used to fluidize and dry the product. Dehumidification coils can also be added to reduce the moisture content entering the dryer.

For closed loop systems, our coils condense and recover solvents from the gas stream, allowing them to be reused in the process. Heating coils then reheat the gas stream prior to returning to the dryer. We can supply cooling and reheat coils installed in a single housing with an integral drain pan.

We also manufacture units with housings, integral drain pans, support steel, instrumentation ports, demisters, access doors, and inlet/outlet transitions.