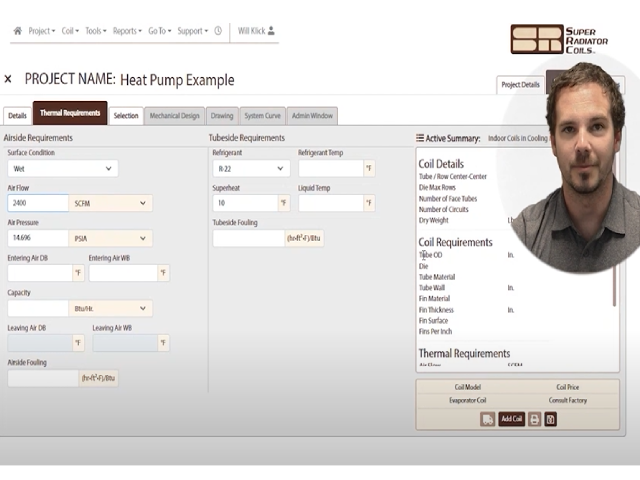

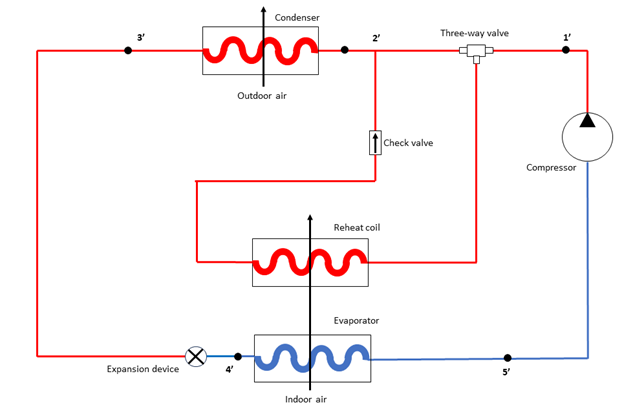

Hot gas reheat coils are a popular and effective means of increasing a system or unit's efficiency. Many of our customers use this coil type in their equipment, so we've launched updated functionality to streamline their design process in Enterprise, SRC's coil selection software. Introducing the ability to rate hot gas reheat coils designed using the hot gas method with just a few easy clicks. Of the three approaches to implementing a hot gas reheat coil into an HVAC system, the hot gas method is by far the most common, and this new functionality makes selecting them much easier. Watch SRC's Will Klick P.E., talk you through the coil design process using this powerful new feature.

Something Powerful

Tell The Reader More

The headline and subheader tells us what you're offering, and the form header closes the deal. Over here you can explain why your offer is so great it's worth filling out a form for.

Remember:

- Bullets are great

- For spelling out benefits and

- Turning visitors into leads.

.png)

%20(600%20x%20400%20px)%20(2).png)