Early 2021's deadly cold spell in Texas in and other areas of the South led to loss of power, water quality concerns for millions, and tragically, loss of life. Abnormal temperatures pushed all manner of equipment past its breaking point, and HVAC systems were hit hard.

Read More

Topics:

HVAC,

Coils,

Quality

Gas-tungsten arc welding (GTAW), or more commonly, Tungsten Inert Gas welding (TIG), is a method of arc welding named for the non-consumable tungsten electrode used during the process. TIG welding isn’t the best option in some industries, but as coil manufacturers, it makes sense for us.

Read More

Topics:

Gas Compression,

Military,

Food Storage & Processing,

Power Generation,

Heat Exchangers,

Nuclear Products,

Expertise,

Quality,

Reliability,

Engineering

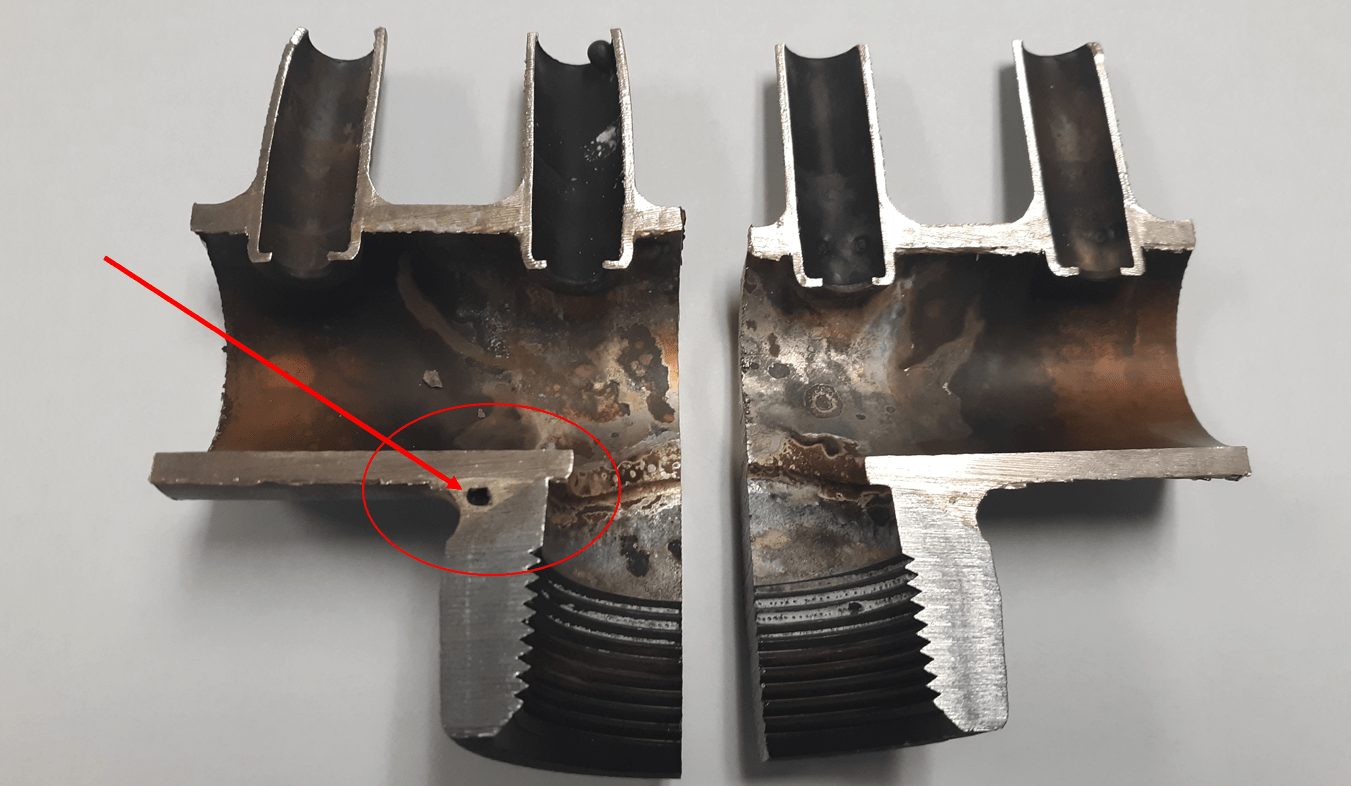

There are terrific braze joints, awful braze joints, and everything in between. Today, we’ll examine one type of defect that can have devastating effects on joint integrity – flux entrapment.

Read More

Topics:

Coils,

Heat Exchangers,

Expertise,

Quality

This article has been updated. It is accurate as of 9/23/20.

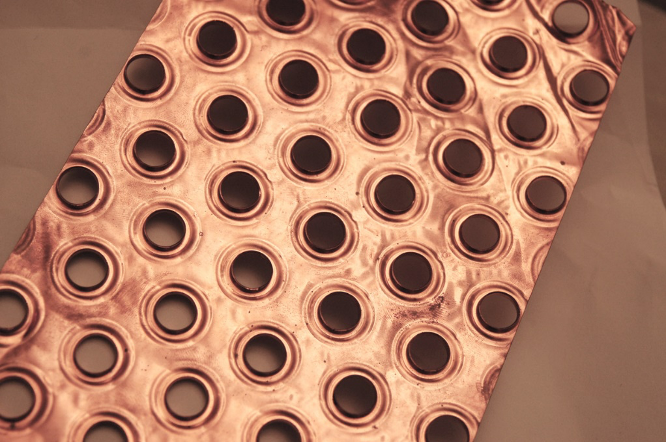

Heat exchangers used for different applications need different design features. For example, in industries like pulp and paper, lower fins per inch (FPI) are often included to reduce airside fouling and to make for easier cleaning. Other applications such as the military are often concerned with weight, which impacts material selection. For this post, we're going to focus on some unique design choices we often include when building heat exchangers for the refrigerated storage of potatoes, onions, beets and other vegetables.

Read More

Topics:

Food Storage & Processing,

Coils,

Heat Exchangers,

Quality,

Reliability

In many of the industries we serve, heat exchangers made with copper tubes and aluminum fin are extremely popular, and very often, these materials are a terrific choice. But copper and aluminum aren’t suited for everything. At Super Radiator Coils, the needs of many of our customers often dictate that we explore and understand alternative materials.

Read More

Topics:

Gas Compression,

Military,

Power Generation,

Coils,

Heat Exchangers,

Nuclear Products,

Expertise,

Quality,

Engineering

We get asked a lot of questions about the passivation of stainless steel welds. Oftentimes, customers want to know what passivation is. Others ask if it’s necessary. Given the number of factors that such a decision hinges on, Super Radiator wants customers to understand the benefits of passivation, and also understand what’s involved in the larger process of treating stainless steel surfaces.

Read More

Topics:

Food Storage & Processing,

Power Generation,

Heat Exchangers,

Nuclear Products,

Quality,

Engineering

Stainless, copper, E-coat, Heresite, or CuNi?

When Super Radiator Coils engineer coils for customers, materials are among our most important considerations. Things like applications, environments, and coil lifespan must all be factored in to the coil’s design. So too must price and industry standards, making material decisions all the more crucial.

Read More

Topics:

Heat Exchangers,

Expertise,

Quality,

Engineering