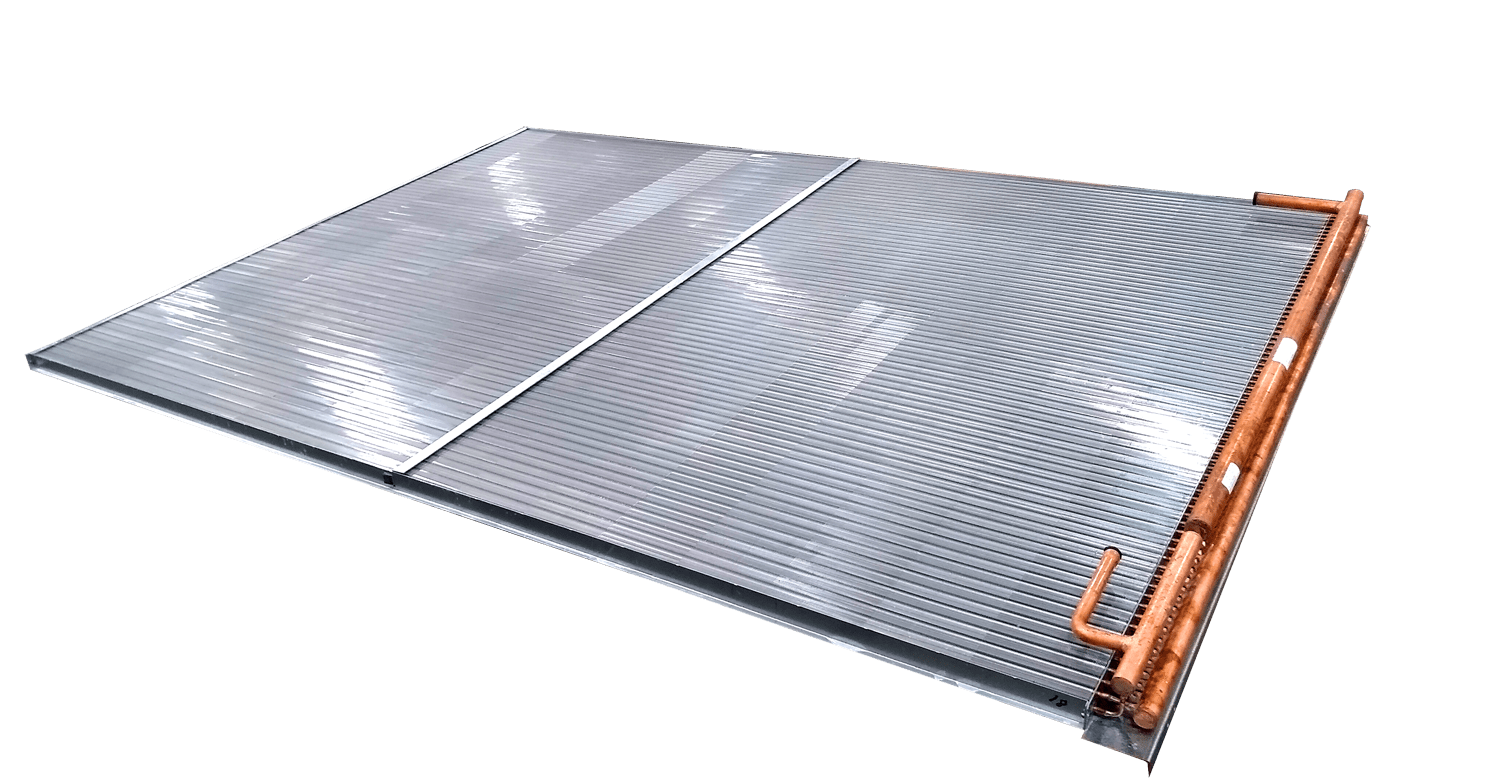

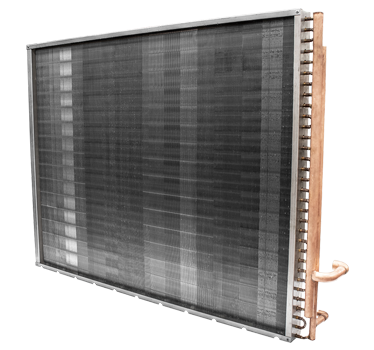

Hot Gas Reheat Coils

In dehumidification cycles, air flows across an evaporator coil where moisture is removed, leaving the coil's surface typically in the low to mid 50sF, which, depending on load conditions, may be too cold for the space.

Hot gas reheat coils work by routing a portion of the gas that would go to the condenser in a standard system to a reheat coil. This coil then brings the air back up to a suitable temperature. Next, the air travels to a supply fan and then to the system's primary heating coil. These coils can be included in the system at the time of construction or added in later.

Our hot gas reheat coils are primarily used in the HVAC industry for applications like supermarket refrigeration and commercial buildings.