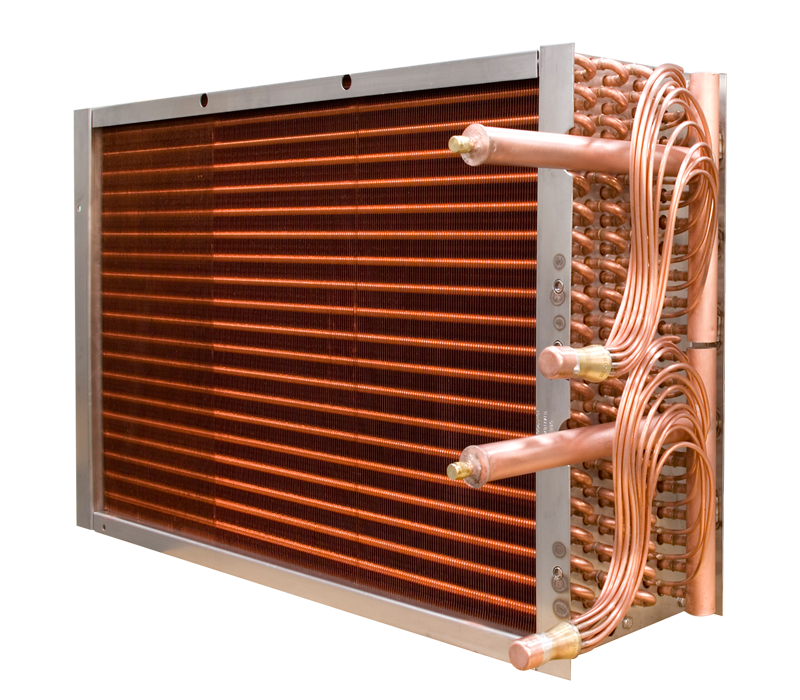

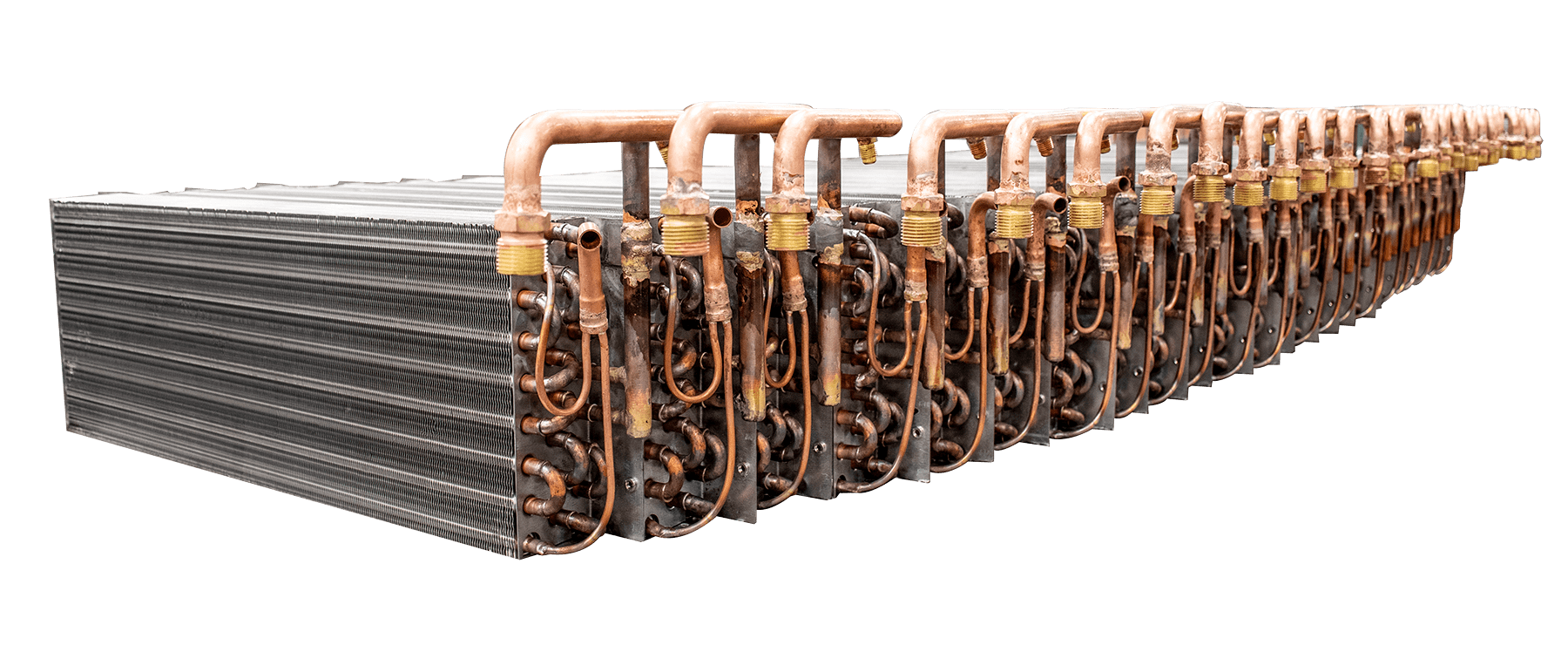

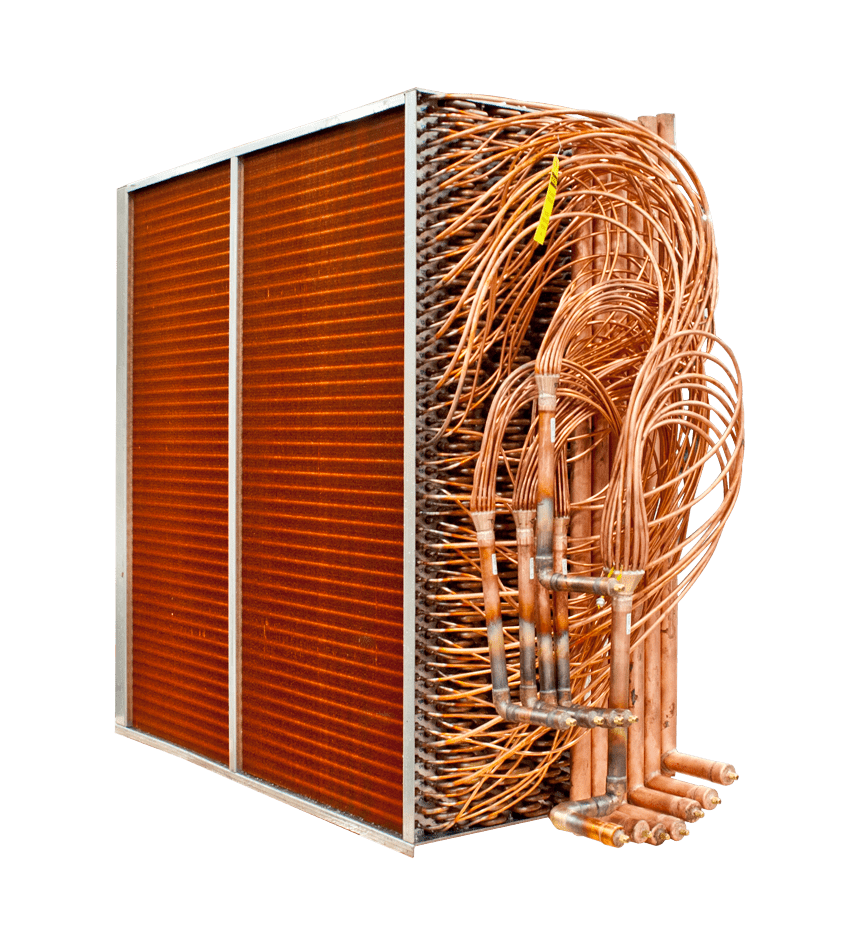

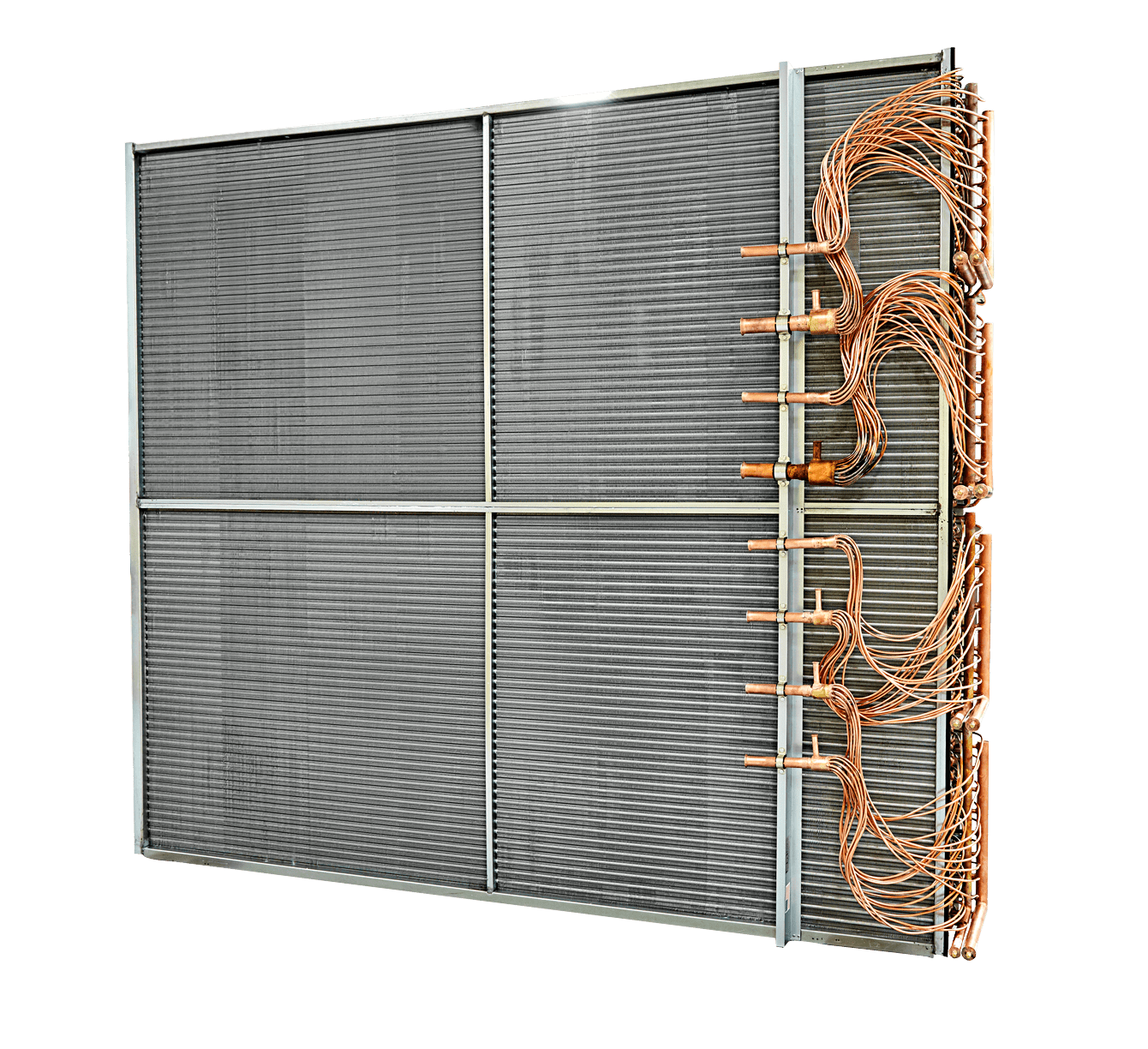

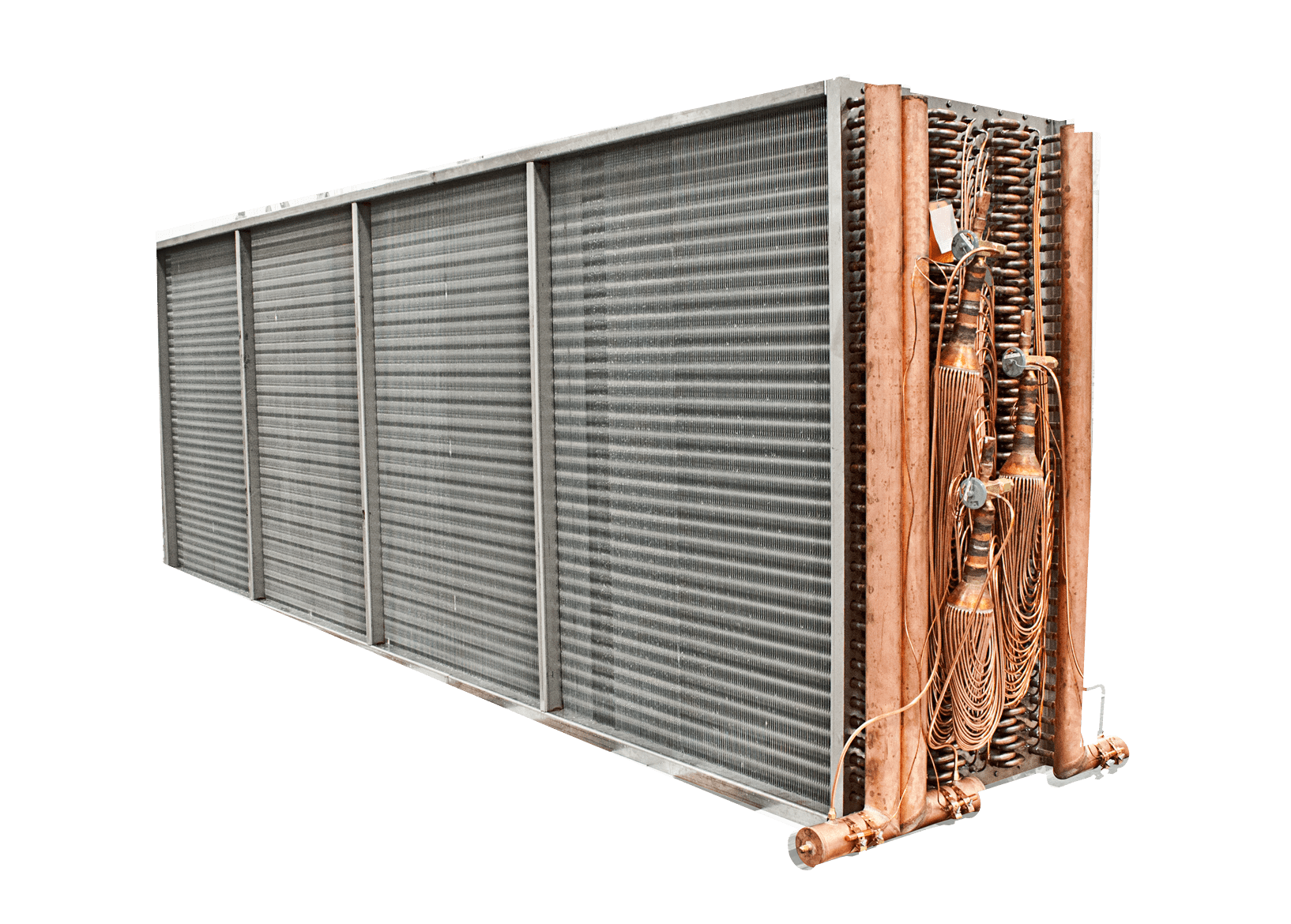

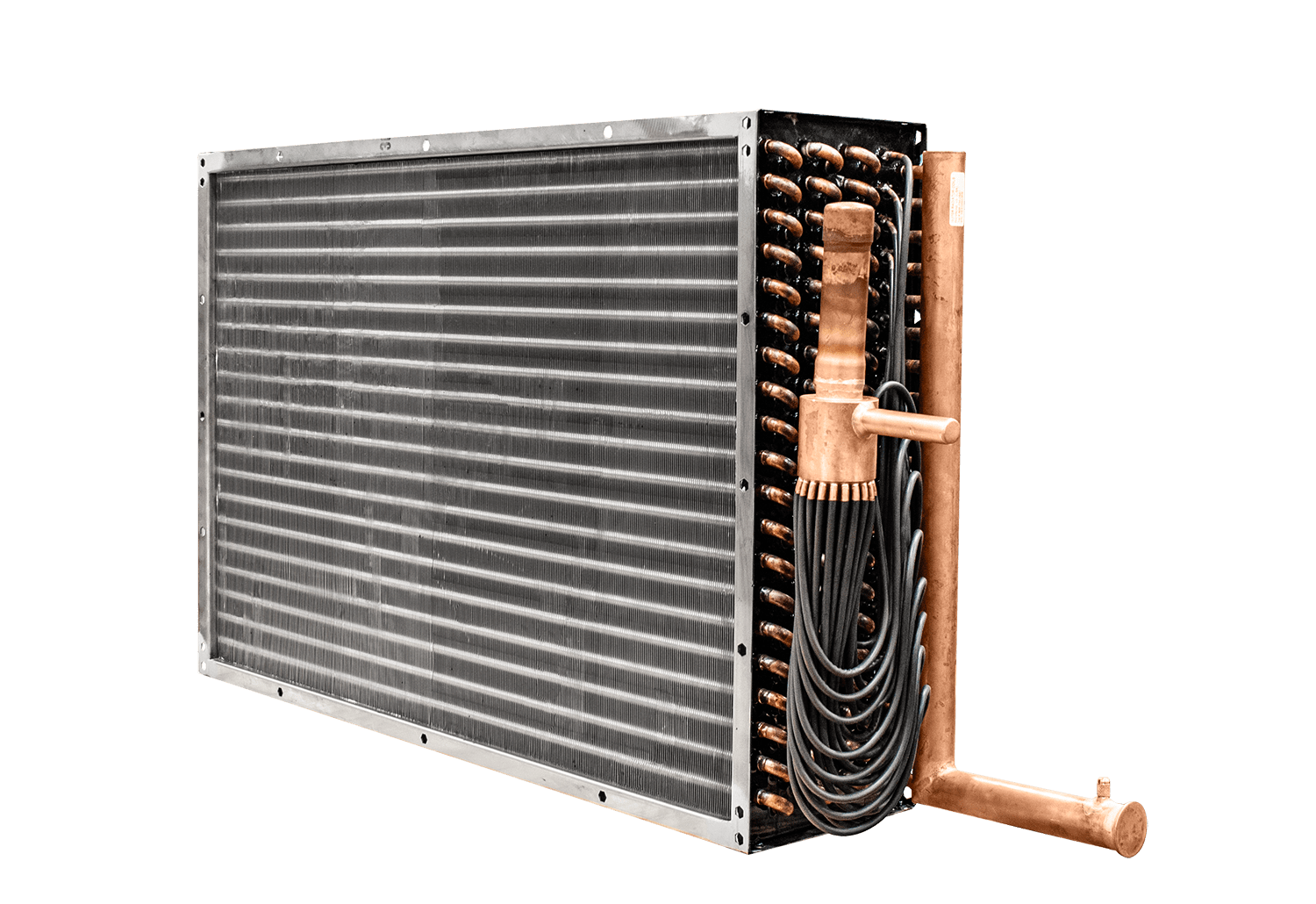

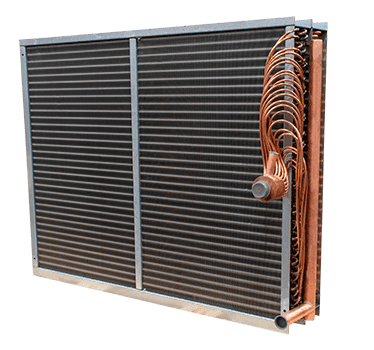

We're a coil manufacturer and heat exchanger manufacturer and among our specialties are evaporator coils to suit any needs. Evaporator coils are a crucial part of any refrigeration system, which is why every one of the 100,000+ evaporator coils we build each year is fully tested to ensure it meets your standards.

An essential component of most HVAC systems, the evaporator coil contains the chilled refrigerant which absorbs the heat from inside the building. As the heat is absorbed, the refrigerant is converted from a liquid to gas moving on to the compressor. Then, via the compressor(s), the heated refrigerant is then moved externally to the condenser coil(s) where it is dispensed to the environment.

In a heat pump system, the operation detailed above is reversed with the evaporator coil expelling the heat into the building.

Our evaporator coils are used in several industries, including gas compression, HVAC, military, transit cooling, refrigerated display cases, data center & electronics cooling, and ground support. No matter your need, we can custom design an evaporator coil for you. Get started with Super Radiator Coils as your HVAC coil manufacturer today!