Using Hydronics to Heat Football Fields

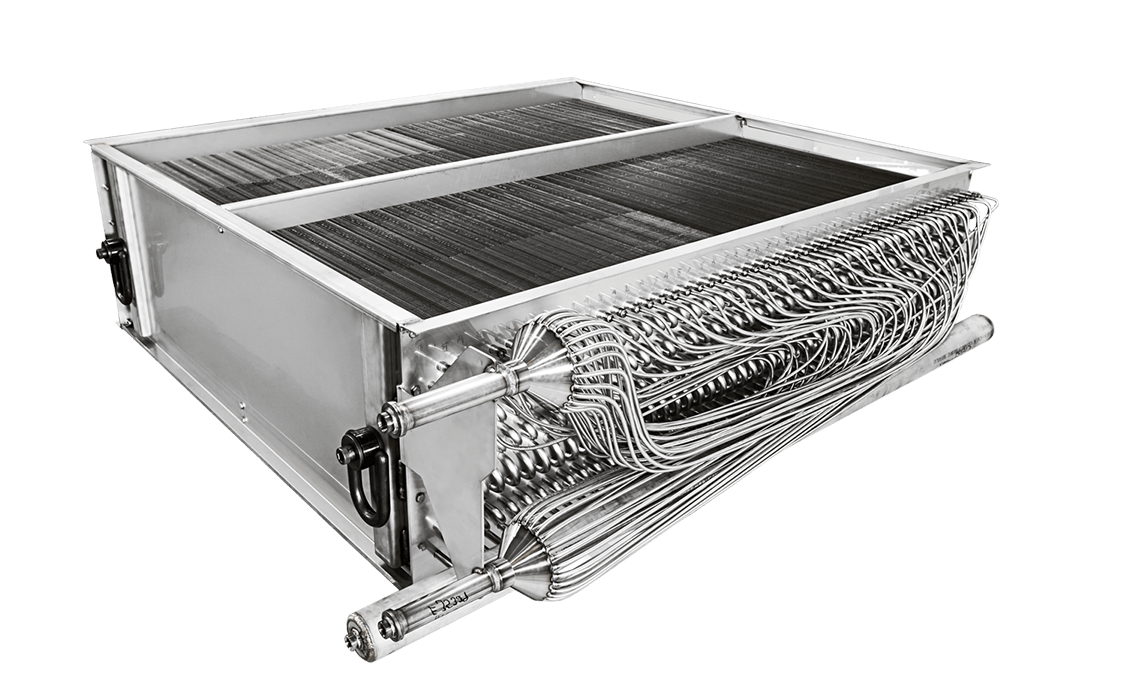

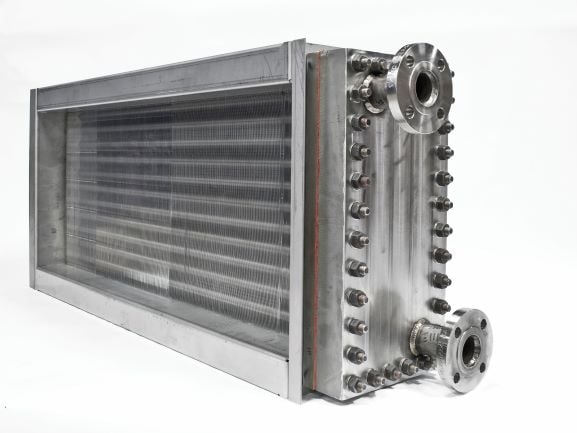

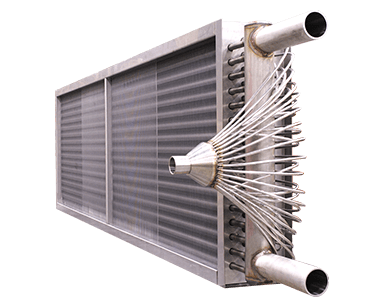

Hydronics systems? Football? While you may not hear those terms in the same breath every day, there’s actually a mind-blowing amount of design and engineering that help keep football field surfaces playable through the cold winter months. First, some context With this year’s big game being played... Learn More

.jpg?width=1024&height=682&name=workers-checking-the-quality-of-freshly-prepared-snacks-at-a-factory-picture-id1150882713%20(1).jpg)