Pollution Control

Pollution comes in two primary forms—thermal and emissions. The thermal variety pertains to the heat that is transferred into a process or fluid stream. The other type—emissions—relate to the reduction or mitigation of VOCs (volatile organic compounds), other solvent based fluids, and inorganic compounds.

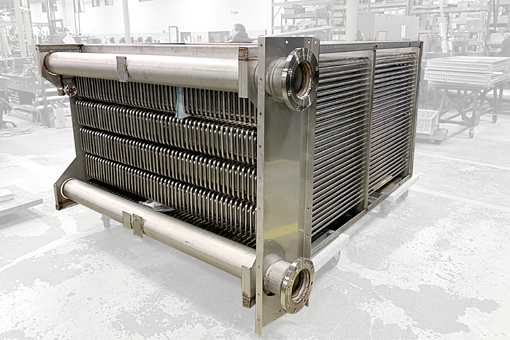

Heat exchangers designed for controlling pollution are found in numerous industries such as pulp and paper, wastewater, power generation, and chemical processing. For each application, Super Radiator engineers work with the customer to understand the correct mass flow and how the components interact throughout the operating range.

If required, housings can be designed and built to support the heat exchanger and the application.