The evaporator coil is a critical part of any compression-expansion refrigeration cycle and is one of at least two heat exchangers used to capture and direct thermal energy for useful purposes in such systems. This article will cover some fundamentals of evaporator coils – their function, componentry, and some information on how to best design them to ensure proper function.

Evaporator Coil Function

Like with the condenser coil, an evaporator’s function is stated in its name. Also called a direct expansion (DX) coil or refrigerant coil, the evaporator is what provides the ‘refrigeration effect’ in most heating and cooling systems, absorbing thermal energy from the space being conditioned and routing it elsewhere.

The process begins when high temperature, high pressure liquid refrigerant coming off the system’s condenser has its pressure rapidly decreased via some type of metering device. This rapid expansion causes the refrigerant to begin changing from a liquid phase to a vapor phase, and the function of the evaporator coil is to complete that process, absorbing thermal energy as it does so.

Upon exiting the evaporator, the refrigerant is a low temperature, low pressure gas. There’s a little more involved in that process, but that’s the basic function. We’ll cover the process in some more detail in the next section.

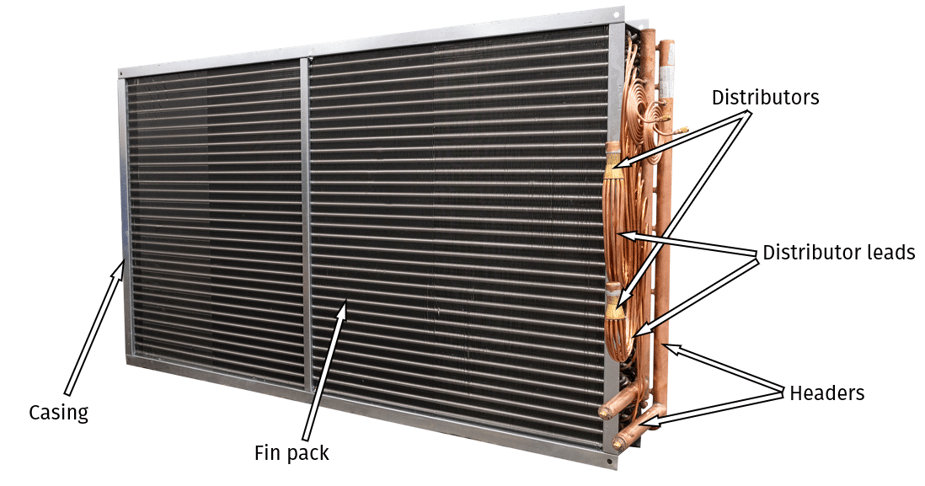

Evaporator Coil Components and Configuration

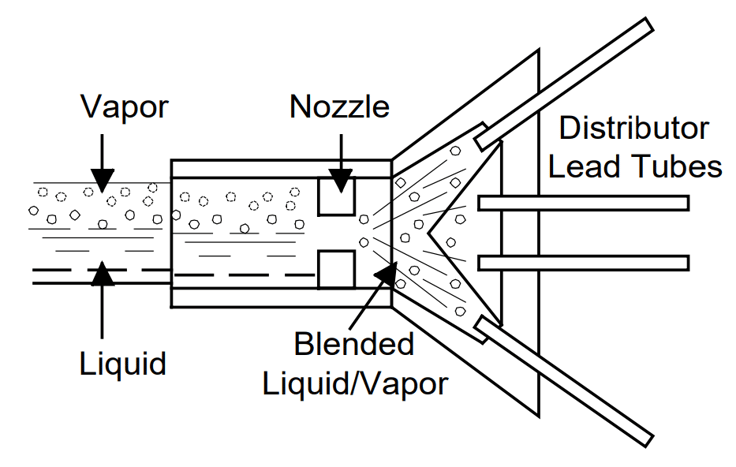

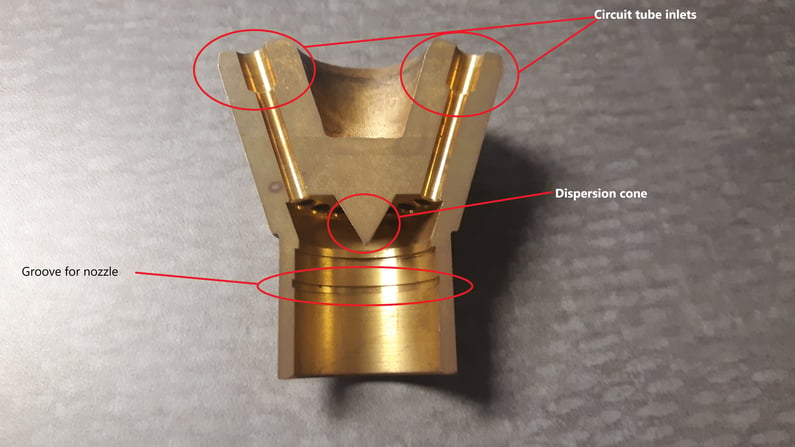

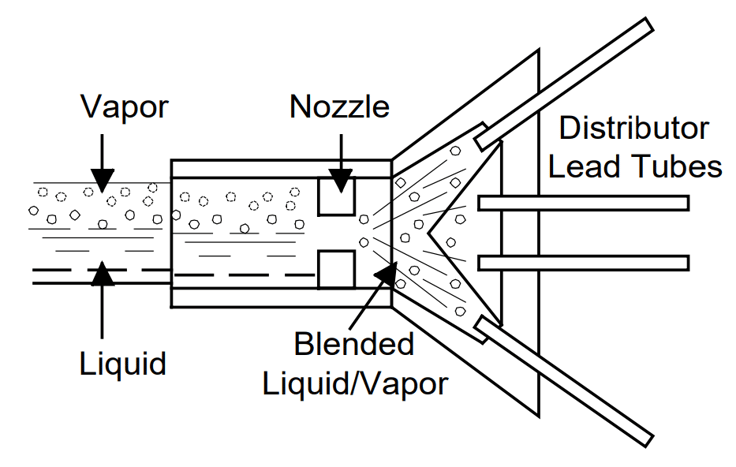

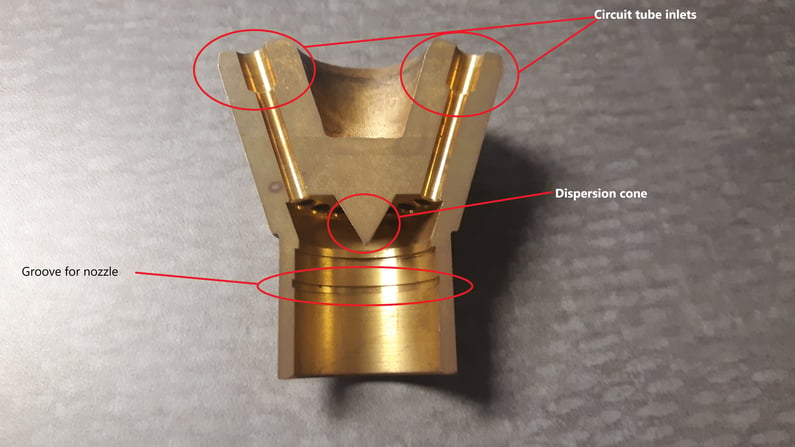

The most distinctive component found in most – but not all – evaporators is the distributor assembly, which serves an important role in the coil’s function. The distributor – and the smaller tubes connected to it, known as leads – essentially act as an orifice and manifold, capitalizing on the rapid expansion of the refrigerant through the metering device by further increasing its velocity and distributing it evenly into the tubes of the evaporator coil.

And, since the refrigerant enters the evaporator as a liquid-vapor mixture, the distributor also facilitates proper mixing of the two, ensuring that tubes are supplied with a consistent mixture as opposed to some tubes receiving gaseous refrigerant and liquid refrigerant being routed to others.

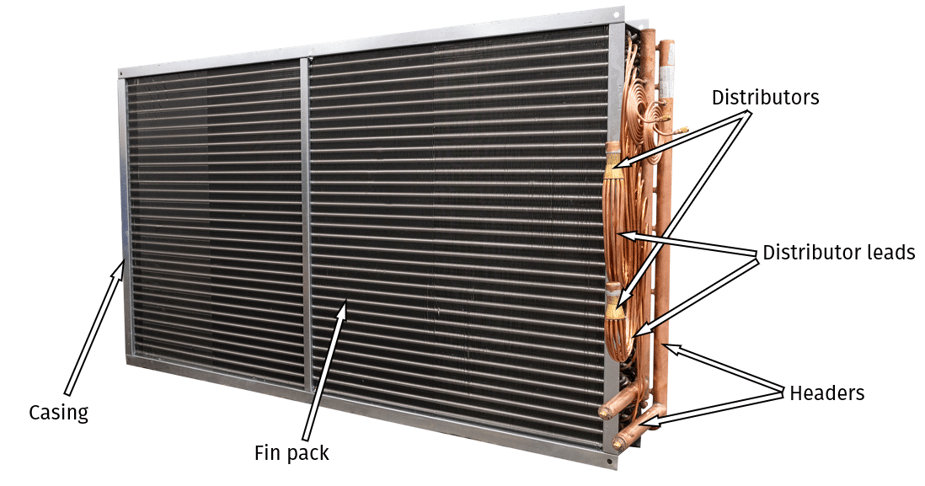

Apart from the distributor, the rest of an evaporator’s componentry can be found across most other coil types. However, the installation configuration of evaporator coils can differ from that of condensers, fluid coils, etc. An A-frame arrangement is a common method used to maximize the coil’s surface area without drastically increasing its footprint, and is very typical in residential applications, but commercial markets sometimes employ this design as well. An example of an A-frame installation configuration is below.

Evaporator Coil Design Considerations

While several design best practices hold true across several types of coils, there are a few design choices that are unique to evaporator coils or worthy of additional attention – specifically distributor/distributor nozzle sizing, circuit arrangement, and fin spacing.

Sizing of Distributor and Related Components

Proper sizing of things like the coil’s distributor nozzle and leads is critical when designing an evaporator coil, as both factors have the potential to affect the pressure drop across the heat exchanger.

- Distributor nozzle size – to achieve the desired pressure drop through the distributor nozzle, it must be properly sized. If the opening is too large, the refrigerant can’t achieve the velocity necessary for effective two-phase flow, whereas an undersized nozzle will lead to excessive pressure drop and reduce the coil’s performance.

- Distributor lead length – distributor leads should be the same length to enable as close to an identical pressure drop between the distributor and each circuit within the coil as possible.

Circuiting

Evaporator coils perform best when each circuit is as close to identical as possible, with the first and last tubes of the circuit on – or near – the warmest air side of the coil. This allows for consistent pressure drop and flash (boiling/phase change) temperature. Such circuiting works to quickly heat the liquid refrigerant entering the evaporator to the flash point and boils off any remaining liquid refrigerant leaving the coil, preventing it from entering the system’s compressor, where it could cause damage.

Also, refrigerant used in evaporator coils typically contains some amount of oil for lubrication, which, for applications above a certain refrigerant velocity, is pushed through and out of the coil. But, for applications with very low refrigerant velocities, that oil can thicken and become harder to move, potentially leading to internal accumulation, which can reduce performance. For such applications, circuits should be designed to be drainable to alleviate the issue as needed.

Fin Spacing

Fin density – especially in applications where the flash temperature is below 32F – is another area of an evaporator coil’s design that merits additional attention. If fins are spaced too closely together, moisture in the airstream can turn to frost on the fin surface, the accumulation of which reduces the coil’s effectiveness and can potentially lead to downstream issues.

Summary

The function of the evaporator – like its aptly named counterpart, the condenser – is to cause the system’s working fluid to change phase from a liquid to a vapor, absorbing unwanted thermal energy and redirecting it as it does so.

The most distinctive feature of an evaporator coil is the distributor assembly, which works to evenly distribute refrigerant to the coil throughout the phase change process, maximizing its ability to transfer heat.

Evaporator coils – like with most types of heat transfer equipment – require navigating a series of tradeoffs to land on an optimal design. A proper design can be achieved by paying close attention to – among other things – the size of the distributor nozzle, circuiting configuration, and fin density.

If you’re interested in learning more about SRC’s approach to evaporator design, or you’re worried your designs aren’t as effective as they could be, give us a call today. We’d love to learn more about your application and look for some ways to improve your evaporator designs.

Don’t get left out in the cold when it comes to heat transfer information and news. To stay up to date on a variety of topics on the subject, subscribe to The Super Blog, Super Radiator's News Feed, our technical blog, Doctor's Orders, and follow us on LinkedIn, Twitter, and YouTube.