In any compression-expansion refrigeration cycle, there are (at least) two heat exchangers working in tandem to condition a space, one of which is the condenser coil. In basic terms, the function of the condenser coil is to take the heat absorbed by the system’s evaporator and move it away from the space being conditioned.

In this article, we’ll expand on the condenser coil’s function, look at some typical condenser coil configurations, and finish by discussing some design considerations for common condenser applications.

The Function of the Condenser Coil

The primary function of the condenser coil is largely what its name implies. By condensing a high-temperature gas stream into a liquid, the condenser coil receives and rejects the thermal energy absorbed by the system’s evaporator.

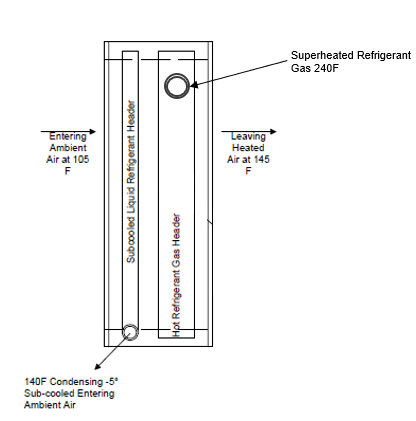

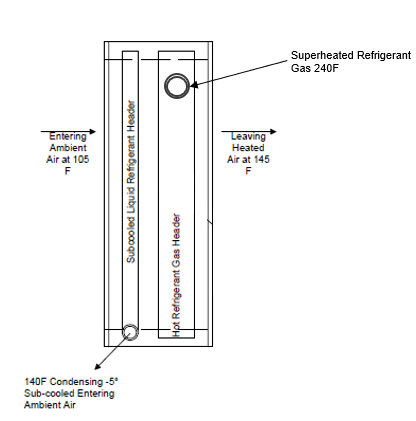

Often referred to as the hot side or the high side of a system, the condenser coil performs a three-phase process to condense hot gaseous refrigerant coming off the system’s evaporator after compression and direct that thermal energy away from the space. Those three phases are:

- Desuperheating – the desuperheating phase is the first step in cooling high-temperature gaseous refrigerant after it leaves the evaporator coil. This sets the stage for the refrigerant to change phase, most of which occurs in the next portion of the condenser.

- Condensing – in the condensation phase, also referred to as the phase change section of the condenser coil, the gaseous refrigerant cools down to a temperature near or equal to the refrigerant’s condensing temperature, where it begins to change from a gas to a liquid, starting as a mixture of the two before changing to mostly liquid as it travels through the condenser’s circuits. This stage is where the condenser performs the bulk of its function.

- Subcooling – the subcooling phase drops the refrigerant temperature below its condensing temperature, leaving it fully liquid in preparation for reentry into the system’s expansion device and then the evaporator. By cooling the refrigerant below its condensing temperature, subcooling protects against flashing caused by the refrigerant picking up any additional heat during expansion on its way back to the evaporator coil.

Condenser Coil Configurations and Components

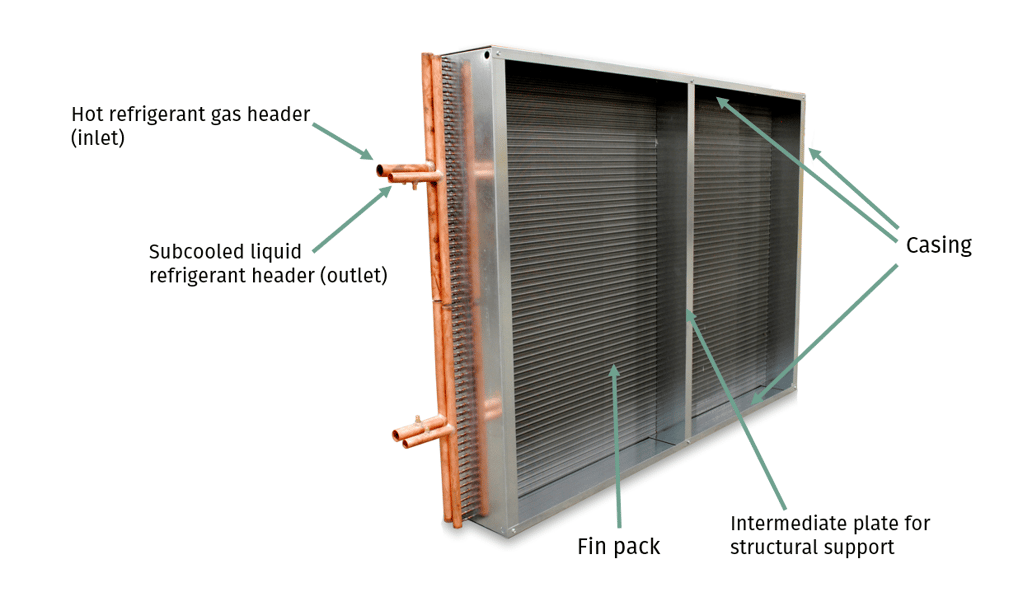

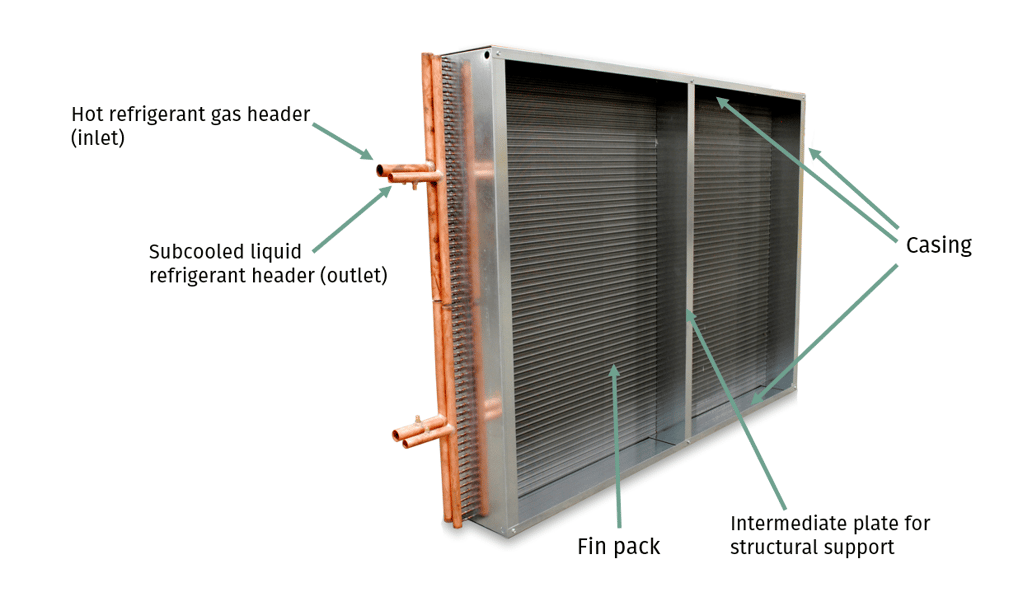

Sometimes confused for fluid coils - which also feature two headers - condenser coils are distinguishable by the size and location of those headers. Unlike fluid coils, which feature a single-phase working fluid, allowing for two headers of the same size, the headers on a condenser coil must be made with pipe of different diameters to account for the fact that refrigerant enters the coil as a gas and exits as a liquid. The diagram below shows some additional componentry found in a typical condenser coil.

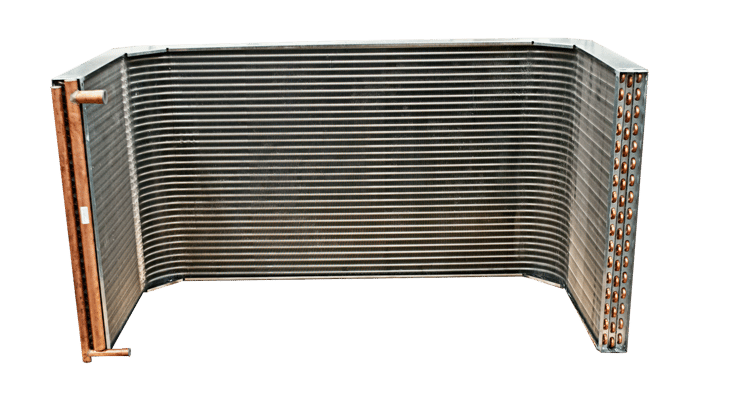

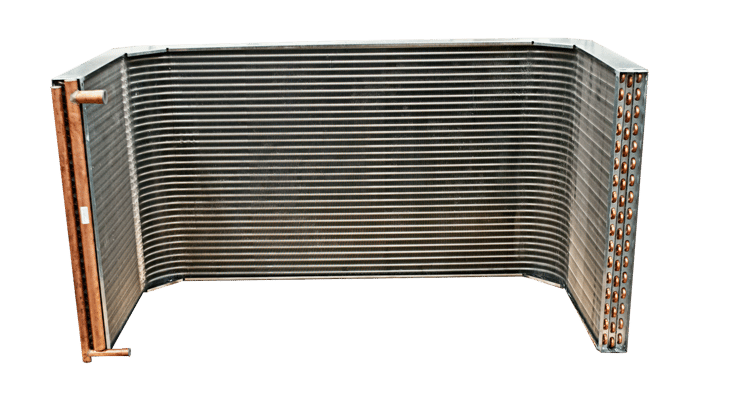

Condenser coils are also sometimes bent into certain shapes depending on the application. One of the more common examples of such a configuration – often called formed condensers – can be found in the outdoor (condensing) units of many commercial and residential HVAC systems. An example of a formed condenser is pictured below.

Condenser Coil Design Considerations

There are a few important facets of a condenser coil’s design that can significantly impact performance and which merit careful consideration. These are:

- Circuiting – condenser coils designed with the proper number and arrangement of circuits provide optimal refrigerant velocity within the coil’s tubes. This enables good heat transfer with reasonable pressure drop and helps push miscible oil through and out of the coil. Circuiting arrangements should be designed to minimize pushing that oil against gravity and should have identical temperature gradients and pressure drops in each circuit.

- Installation orientation – understanding the orientation of the coil's installation relative to the application’s airstream (vertical, horizontal, angled, etc.) is another important consideration when designing a condenser coil. Failure to do so can cause issues like those that result from improper circuiting, including increased pressure drop and variations in refrigerant velocity. These can contribute to the buildup of oil, which can lead to excess oil flooding the condenser’s tubes. That oil can then insulate portions of the tubes’ heat transfer surface, which impacts coil performance, reduces the amount of oil available for proper compressor lubrication, and can lead to flooding of the evaporator if enough oil builds up and is forced out of the condenser at once.

Summary

A properly designed condenser coil is a critical part of any HVAC-R system. While their design can be considered less complex than that of an evaporator coil, a thoughtful examination of its design is warranted. Not only will optimal designs eliminate the potential for some of the issues mentioned above, they can also contribute to improvements in the performance and efficiency of your system as a whole.

If you’re an OEM and you think you could be getting more out of your condenser coils, give us a call today. Our engineers would be happy to pour over your design and look for opportunities to gain performance or improve efficiency.

Don’t get left out in the cold when it comes to heat transfer information. To stay up to date on a variety of topics on the subject, subscribe to The Super Blog, our technical blog, Doctor's Orders, and follow us on LinkedIn, Twitter, and YouTube.