Super Radiator has served the food manufacturing sector for decades. It’s one of our bedrock industries and over the years, we’ve come to learn quite a bit about food production facilities, their environments, and coil designs that work well there.

For this post, we’ll look at some of the elements of food manufacturing facilities that make them inhospitable to metal componentry and some design choices that can help combat them. We’ll talk about:

- Corrosives in food production facilities

- Acids from foods

- Chemicals found in cleaning products

- Water and steam from production processes

- The impact of high temperatures

- How Super Radiator’s expertise can help

Corrosives in Food Production Facilities

Some of the most common sources of corrosion in food manufacturing plants are things like:

- Acids from foods

- Chemicals found in cleaning products

- Water and steam from production processes

Acids from Foods

There are dozens of foods and drinks that can cause metal food processing equipment to corrode over time. Things like soups, beef, beans and cheeses typically fall in the range of mild to moderately acidic – with a pH between roughly 4 and 6. Foods with a pH of 4 and lower feature some familiar enemies of metal food processing equipment, such as tomatoes, salad dressings, vinegar, citrus juices and cola. Processed cured meats like pepperoni and salami are also notoriously acidic. In the presence of oxygen, these substances will lead to corrosion.

Chemicals Found in Cleaning Products

Public health and safety are paramount in all food and beverage production. With several high-profile product recalls occurring in recent years, and as the food manufacturing sector continues to grow and modernize, regulators have placed an understandably high importance on ensuring that food processors aren’t getting people sick. That level of oversight and scrutiny has led to measures such as enhanced cleaning procedures and stronger detergents, among others.

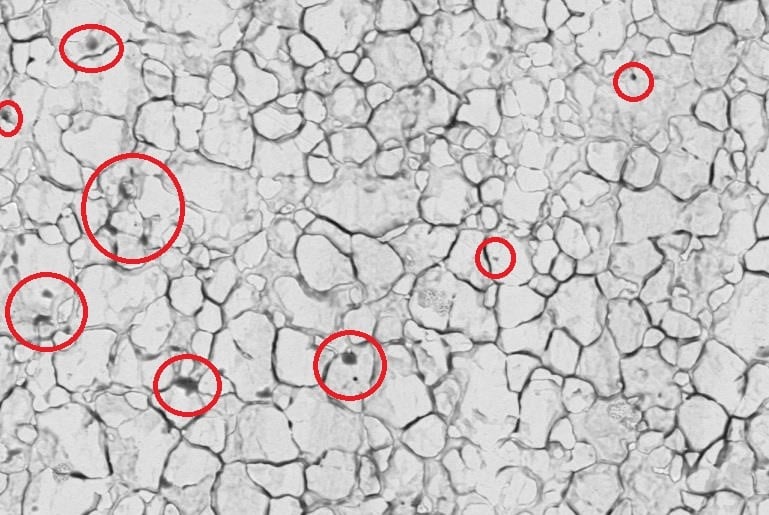

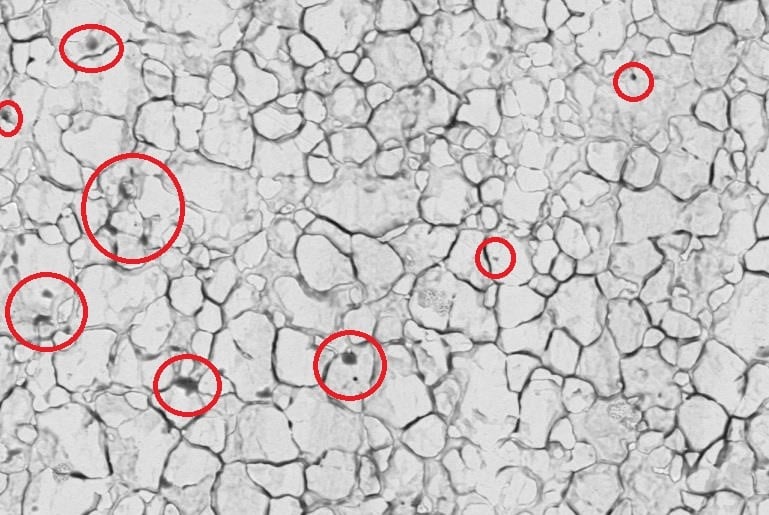

Ironically, many of the substances used to sanitize food processing equipment can contribute to its corrosion. These cleaning substances contain a number of ingredients, which can be basic, like sodium carbonate and bleach, or acidic, like citric acid or sodium citrate, both of which can corrode metals by way of multiple mechanisms. Even stainless steel - lauded for its corrosion resistance - can fall victim to what's known as intergranular corrosion when exposed to chlorides (pictured below).

Water and Steam from Production Processes

Water and steam are fixtures in most food manufacturing environments, where they’re used for several functions, including cleaning. High pressure water and steam are often used in conjunction with the aforementioned detergents, serving as the vehicle by which they’re introduced to food processing surfaces. Great for cleaning, not so great for protecting equipment from corrosion.

The quality of the steam and water being used can also contribute to corrosion. The use of steam containing corrosive non-condensables and poor-quality water can introduce more potential corrosive contaminants.

The Impact of High Temperatures

In addition to exposure to harsh detergents and acidic foods, food manufacturing equipment has to stand up to high temperatures used in processes like cooking, drying, pasteurization, and others, functions that are usually carried out by heat exchangers.

For most types of steels, the temperatures present in food production environments – 650F at the high end – are well within the range of what they can withstand. But over time, these temperatures can cause issues of their own.

At temperatures in this range, concerns regarding material integrity are often the result of cyclical loading. This occurs when equipment is regularly heated and cooled during its service life. Over time, thermal cycling can accelerate the rate at which metals like steels fatigue, weakening the metal and potentially leading to premature failure.

How Super Radiator’s Expertise Can Help

So, by now you’ve likely got a pretty good idea of the kinds of environments where these heat exchangers are installed. They’re hot, they’re corrosive, and downright inhospitable to all types of equipment. SRC has built equipment for these environments for decades and we’ve learned some valuable lessons along the way. For this section, we’ll detail some:

- Design considerations for high temperatures

- Designs considerations for corrosive environments

We’ve broken down these factors into two groups for easier reading, but there’s definitely a middle section to this Venn Diagram. Both high temperatures and corrosion can exacerbate symptoms caused by the other when both are present.

Designs Considerations for High Temperatures

As is often the case, material selection has a major impact on a coil’s ability to withstand harsh environments.

For example, we had customer whose stainless-steel oven coils were failing prematurely, lasting only about a year after installation. After an engineering analysis, it was clear that cyclical loading was weakening the steel, leading to failure at the joint where the tubes met the header.

So, we designed an upgraded coil with headers and tubes made from a super-austenitic stainless steel alloy, which was able to withstand the high temperatures much better. That switch helped to strengthen those joints, but didn’t completely solve the challenge.

For added resistance against the effects of the cyclical loading, we designed a tube reinforcement affixed to the high-stress areas of the coil. The tubes were welded to the added reinforcement, which was then welded to the header.

By thoughtfully selecting materials and understanding the forces at play, we were able to drastically reduce the frequency with which our customer needed to replace their coils.

Design Considerations for Corrosive Environments

We’ve covered how chemicals used to sanitize food production facilities can cause metals to corrode. And while not all our coils are food-grade, many of the food processing coils we build support food-grade equipment. Plus, regardless of their specific function, virtually all equipment in food processing plants is subject to regular and vigorous cleaning.

In fact, many plants run a third shift whose sole function is to clean the facility after a long day of production. And, as we covered, the detergents used for this critical operation can exacerbate corrosion issues.

In those cases, we will typically opt for stainless steel or a stainless super alloy, which can be electropolished prior to installation. Electropolishing and other surface treatments help to eliminate contaminants or impurities from the metal’s surface – start clean, stay clean is the idea. These surface treatments also help rid the metal's surface of burrs and nicks where food material can become lodged, which can be a source for corrosion.

Material compatibility is another dynamic to consider. Our food processing customers often request 304 or 316 stainless steel, but all-stainless coils are more costly, and for applications without direct exposure to corrosives, different material combinations may be viable. In such applications, though, the use of dissimilar metals introduces the potential for galvanic corrosion. We know that in the presence of an electrolyte, contact between metals with differing electrode potentials can cause corrosion, and food processing plants contain plenty of potential electrolytes – food particles being one example.

Food production applications are unique and rife with potential pitfalls, even for the experienced engineer. SRC is here to serve as your expert partner in the design and manufacture of food processing heat transfer equipment. If you’re replacing equipment more frequently than you’d like to be, or looking for someone to take thermal engineering off your plate so you can focus on other priorities, give us a call. We’d love to talk about your application. Or, if you've already got an idea of what you're looking for, submit a quote request and an engineer will follow up with you shortly.

And check out the links below for some more articles from our Application Spotlight series.

Don’t get left out in the cold when it comes to heat transfer information. To stay up to date on a variety of topics on the subject, subscribe to The Super Blog, our technical blog, Doctor's Orders, and follow us on LinkedIn, Twitter, and YouTube.