There are a few primary means of differentiation between an Industrial Steam or Steam Distributing Heat Exchanger and a Commercial Steam or Steam Distributing Coils - the environment and conditions, materials of construction and certification.

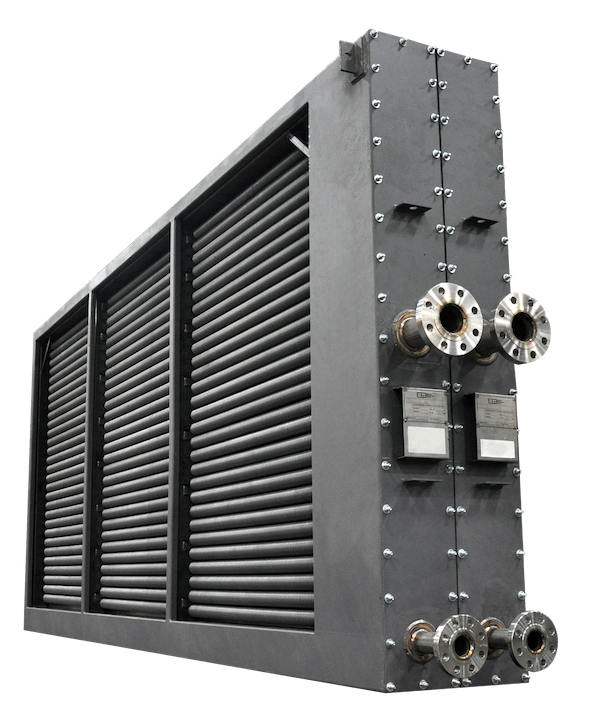

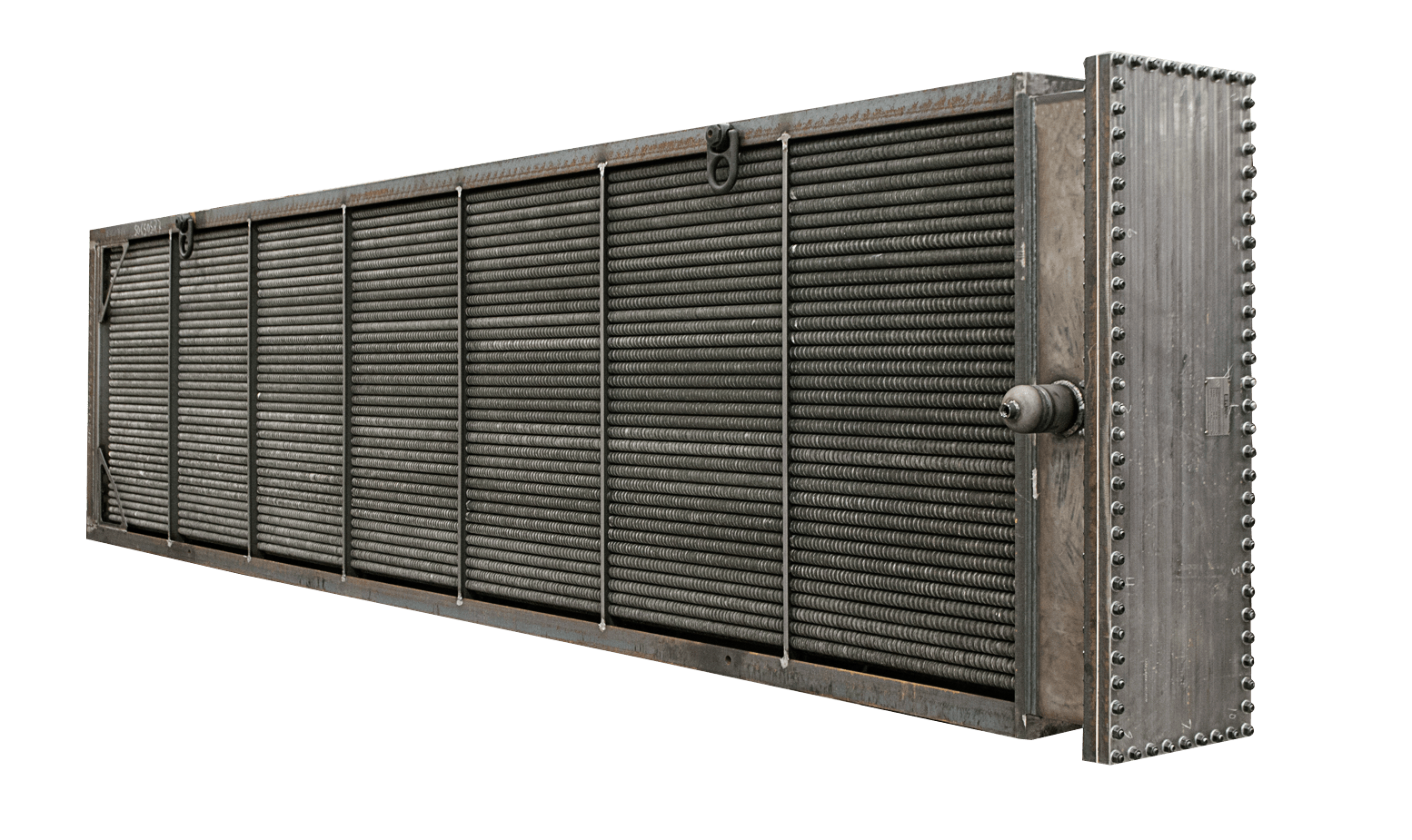

The environments that Industrial Steam or Steam Distributing Heat Exchangers are placed in are typically harsh and aggressive. Power plants, chemical processing facilities, and waste heat recovery systems are all examples where an Industrial Steam and Steam Distributing will live and operate. Their environment and realized conditions drive more robust material selection. Material such as 300 series stainless steel or with heavy wall or gauge thicknesses.

The US standard for code compliance is the ASME Section VIII, Division 1 Code. SRC will apply either the U or UM stamp based on the volume and pressures of the application. Additionally, for shipment into Canada, Canadian Registration Number (CRN) or Europe, the Pressure Equipment Directive mark (CE - SEP, Level 1 or Level 2) can be applied.